It can be pretty tricky for you to carry out some challenging tasks regarding hand drills. The tasks may involve drilling multiple holes of varying depths, widths, and angles.

Sure, you could have survived in the past with a reliable hand drill, but I am sure using a drill press will make things easier for you. And that’s why I am here with the best drill Press for 80 lower to make styling work quite comfortable for you. I hope you can find out the preferred one.

DIYers pick: Top 5 Best Drill Press for 80 Lower

With so many unique features at such a low price, this is one of the best drills at our list! This drill press for 80 lower has different speed levels ranging from 740, 1100, 1530, 2100, and 3140 RPM to complete any drilling project. The speed functions are also easy to switch forward and backward.

Top Drill Press for 80 Lower

WEN 4208T: Best drill press for 80% lower

The Wen drill press setup includes a chuck with a half-inch key, so no problem. Besides the key holder, you have access to the boat’s key vault. Since it is often difficult to get the proper deep poses on time, many people sometimes exaggerate. This is why the WEN 4208 includes a linear depth stop with a clear marking path.

Moreover, the induction bearing design ensures smooth and balanced operation and makes the motor durable. This tool has the best drilling speed – 80% less. So now you can safely drill and make sure you behave accurately and straight without overdoing it. And all this is possible because the shaft moves 2 inches with ideal performance.

It consists of a sturdy cast-iron frame, table, base, and head for drilling precise gaps and making the boring process easier for the user. WEN should be your first choice if you are thinking of the best drill press for 80 lower for simply drilling any material.

- Strong cast iron base, frame, and head make it sturdy. This ensures long-term use! WEN operates at five different speeds for precise drilling which is 3140, 2100, 1530, 1100, 740 rpm. The shaft can move up to 2 inches and has locking depth stops for precise drilling. Comes with a height-adjustable work table for more comfort and flexibility. The 8-inch 5-speed WEN is close enough to reduce your desk space yet drills through wood, metal, plastic, and other elements.

- Some disappointed clients complained about the amount of work. Most of the time, there are easy ways to overcome this difficulty. Likewise, It may happen from lacking power issues; you can check and fix it quickly. Again, some users report that they have a nasty chuck issue. Surprisingly, you can quickly fix it with home remedies.

Runner Up Drill Press

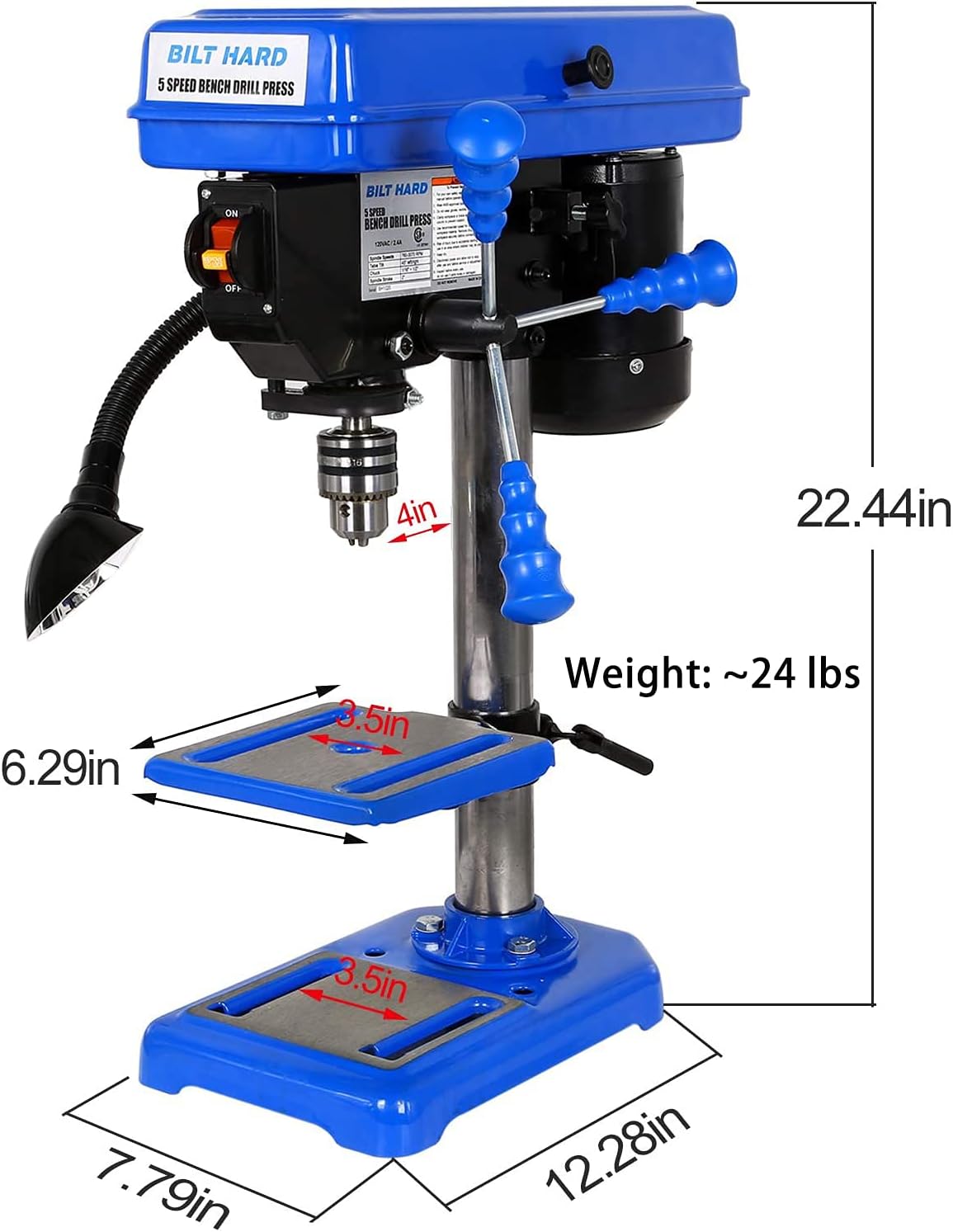

BILT HARD: Best Benchtop 80% lower drill press

Don’t be fooled by the size of Bilt Hard 8. It may seem small and harmless, but believe me, it’s quite handy! This drill has an 8” stand, a chuck, a 2” shaft, and a 2.4Amp induction motor, so while this drill may seem small, it can drill wood, metal, and plastic very quickly.

Changeable speeds (3070 2180 1630 1150 760 rpm) let you to determine the perfect working rate for your task. It makes work more convenient and accurate than a hand tool. This item includes 2 and 1 /2 “to 2 and 1/10″ open jaws, 13-piece set from 1/16- 1/4 “, versatile and required for Numerous applications.

Precise drilling and unrivaled durability are what this drill promises. Therefore, the table frame is made of cast iron. The good news is that the table can be tilted 45 ° to the left and adjusted to your liking. It has pre-drilled holes in the base so you can conveniently mount it on a bench or workbench.

In addition, this 80 lower drill press is compatible with many parts. The bit “bit” allows it to accept bits from 1/16 “to ½.” This drill requires re-drilling due to the depth gauge with the gauge.

In addition, the depth lock position is legible. It is a well-designed, reliable, versatile, and mighty instrument that can manage anything a hobby press or limited production press needs.

- Certified by CSA, BILT HARD is committed to quality followed by upper-class client service delivered immediately by the maker. 8 “rotation, 2” suspension travel, 1/2 “wrench, 2.4A (1 / 3hp) induction motor, miniature yet powerful enough for drilling. Compact Design: The workbench frame contains cast iron for strength and precision drilling. The work table can have a 45 degree left and right angle for corner drilling.

- Chuck can wobble sometimes. You can proceed with caution in solving this problem. Again, some users experience minor audio problems, although this is not a significant problem and has an effortless fixing.

Best Overall

WEN 4210T: Drill press for 80% lower with Laser

The Wen drill provides precision and efficiency in drilling. The drill is incredibly versatile with a cast iron base. There are many adjustable functions such as height, speed, angle, etc. Sidelights allow the operator to work away from shady obstacles. When you combine it with a laser guide, you get the perfect combination of precision.

This is an excellent tool for all sorts of projects. You can set the drill to five positions, from 600 to 3100 rpm. The axle travel is ½-2 inches and has a linear locking depth function that is easy to read. This ensures that you can repeat accurate drilling with ease.

Moreover, the powerful 3.2 amp motor is durable and has good torque. Also, the motor is equipped with bearings for balanced performance and long service life.

Besides, the work table is a high-quality cast iron work table. The rigid construction ensures that you have a durable, reliable, and robust machine at your disposal. You can easily adjust the height of the grate and pin to ensure accurate drilling for demanding tasks.

Again, The X-Pattern laser is designed to block any puncture point. It has an inch chuck that matches well with the JT33 tapered shaft. In addition, you can reduce shaft shock by adjusting the depth lever for more accurate drilling. And its flexibility makes it the best drill press for 80 lower.

- If you want precision, a laser guide is essential for a ray machine. It improves accuracy and speeds up work. This bench drill is a great way to learn how to drill. It is competitively priced and easy to use, making it attractive to newbies. 2/2-1″shaft is casual to read, providing additive depth of cut for precise and quotable drilling functions. It includes 1mW Class II laser, hole saw, 1/2 “chuck and wrench, everyday tool for quick assemble.

- Some buyers say that this is not a product with quality materials, but mostly positive reviews show the opposite result. Again, some adverse reports on the laser stopping issue, though it is not a big concern. You can restart the tool to fix it.

Best Benchtop Drill Press

Grizzly: Best Benchtop milling 80% lower with drill press

We have put this item on our favorites list because of its portability. Like the Bilt Hard 8, this one is also a tiny drill. Just looking at the weight, 34lbs, you immediately understand how compact this drill is.

This is an excellent choice for small workshops or underground hobby rooms. Its 8 ” 1 / 3hp rotary engine is powerful enough to handle most projects using various materials.

This item has a cast iron base, is puncture-resistant to a small degree, and is lightweight and portable. As a result, you can take it wherever.

Moreover, this bench drill offers five speeds from 740 to 3140 rpm. The chuck fits into a tapered shaft bore and accepts parts from 1/16 “to 1/2”.

The work table is 6 1 / 2″ square and tilts 45 degrees left and right. It rotates 360 degrees around a steel column, is cast iron, and has two 5/8″ and 4-3/8″ slots in the center. Besides, you can easily alter the height above, below, and around the rack using the table height lock lever.

Grizzly Industrial also offers a one-year limited warranty (standard on all products) on the G0925. Indeed, this is the best baby drill in the 80s and promises to provide the best service for light drilling.

- This item is too light, so you don’t have to be exhausted to move it around. The Company has designed this item as strong and flexible. In this way, it is suitable for a variety of drilling materials. The table can easily adjust the height using the table height fixing levers. The T function with two heads allows the drilling machine to achieve the required performance. It is too durable with its material and looks a little more stylish than other foreign models.

- Some users are not satisfied with the small 1 / 3hp engine. But it has a significant impact on work! And some client claimed for its plastic parts, such as the shaft collar, as it is breakable. Surprisingly, they don’t have custom reports on this issue.

Small Drill Press

Euro Tool: Best Small Benchtop 80% lower drill press

The newest and arguably the best on the budget is the Euro Tool bench drill. Weighing only 11.53 pounds, this small, eco-friendly machine is perfect for a small store. It is the ideal tool for making jewelry of any size or for small crafts.

The stable base has a solid construction that can hold any part securely. The turntable rests on a base and is suitable for various stock sizes. This item comes with easy to assemble feature and effortless readable instruction which is easy to understand.

Surprisingly, you can increase the speed up to 8500 RPM. It has a 6 to 3/4 inch square base on each side. It comes with a height adjustment that allows you to lower and lower the arm and adjust it to the height that best suits your needs.

Changing belts here is also very simple, take off your helmet and put on a new belt. It has a reliable motor that provides good precision and accuracy when working. In addition, this model is of high quality, flexible, and excellent price. Therefore, he deserves his place as my first choice.

Moreover, it’s cheap. If you don’t have experience building any of them, you won’t have a problem, as the instructions for this tool are written in simple language and are very easy to obtain. In short, this best benchtop drill press for 80 lower is the perfect addition to any semi-professional workshop.

- The drill press will save you time! This small tabletop tool works efficiently, is less costly, and allows you to use a significant amount of space on your deck. The lightweight nature of the tool also increases portability. Depending on the project, it is ideal for contractors who need to move a machine from one location to another. It has an adjustable stop with a gauge, a steel base, and ahead, making it very durable.

- You may not be able to handle heavy commercial or professional projects. Best suited for small drilling jobs or home carpentry jobs. Notably, this drill has many moving parts. If you plan to buy this drill, you need to know its features to use it correctly. Otherwise, you can’t get the best service.

How to Finish an 80% Drill Press Lower?

If you’ve already decided which drill to buy for the lower 80s, it’s time to figure out how to do it.

By following this short step-by-step guide, you’ll learn what it takes to turn an unfinished 80s rifle into a fully functional AR rifle.

The first step (Jig adjustment: 80 percent lower jig on the drill press)

The choice is an essential part of the80% lower drill press.

To adjust the pattern, attach the steel pins along with the shaft. Place the receiver on each board and install it immediately.

2nd Step (ordering a template)

Align the same holes as in the side plates and drill them. You can now place the template over the template using special tools such as hex wrenches and hex head screws.

3rd Step (create a pilot template below)

It’s time to do the same with the pilot. You will see that there are already many holes in the pilot model. Therefore, use the hex wrench and hex screws to align the pilot pattern next to the pattern set.

4th Step (secure the vise)

After tightening all the knots in the jig, fix it in a working vice for better stability. Make sure the screws are securely tightened and tightened before starting work.

5th Step (set the bit)

Once everything is in place, remove excess aluminium by drilling pilot holes. You now have an entry point.After the recipient, repeat the same procedure with the template. Remember to remove dirt from time to time for accuracy.

6th Step (Drill a hole through the receiver)

It’s time to work with a grinder instead of a track for this track. Remove the piece carefully and plug in the final grinder to continue the process.

Be sure to use the correct size and specifications of the grinder for the drill press and the 80 bases you are using.

Also, use additional gears such as brake calipers to adjust the kit properly. Don’t forget to make the required cuts and continue until you reach the desired depth. Finally, make sure to clean up punctured parts and dust so that you have a clean control point to work with.

7th Step (create space for the trigger socket)

Then it’s time to block activation. Adjust the required sander ends as needed and drill the holes for the receiver, and trigger accordingly.

The final step (Drill Holes for the Pins)

In the last step of the day, use an appropriate piece (usually an inch) to drill holes at both ends of the receiver, after which you will need to hammer holes with another, more comprehensive selection.

You may also need additional trigger holes. After you have finished all drilling, bring all the pieces together to form your AR-15.

Drill Press vs. Router

When you have to choose between a router and a drill, it means you are selecting a finishing jig. When the milling 80 lower with drill press initially hit the market, the router-based jig was employed to complete the jobs. Notably, they are now available on the market.

Drill press machines are essential for router-based jigs to drill the lower components kit’s pinholes. Nowadays, drill press machines are more crucial to utilize for milling reasons.

Factors to pick the Best drill press for 80 lower

It doesn’t take much experience to drill and cut the 80 lower. But the tools you use to drill it are essential. So what do you look for when buying a drill? Use these tips to find the best drill press for 80% lower.

Firstly: There are two types of drills, benches and stationary models. Most desktop models are lightweight, portable, and compact. Stationary models are heavier, stronger, and more durable than DIY tabletop models. It is a good idea to have at least one drill in your home or office.

Secondly: It would be helpful to analyse the depth stop, swing, speed, and power of your drill before purchasing. Depending on the durability and size of your project (s), you should choose the drilling machine that suits your requirements.

To help you, in simple terms, we will try to explain the factors.

Depth stop: The depth stop helps you make many consistent and accordant holes. This is a valuable feature for drilling a receiver with a bottom value of 80.

Swing: The swing is the distance between the drill center leg and the shaft, multiplied by two. This determines the maximum width of the preferred material that you can insert into the hole when drilling in the center of the workpiece.

Speed: Most drills have adjustable speed levels making them flexible. For drilling in rigid materials such as metal, you need lower speeds for clean cuts. For softer materials such as wood or plastic, you will need a faster temp.

Horsepower: The higher the power, the more powerful your drill will be. So, if your project requires you to drill thick and heavy objects, choose a high-power drilling machine.

Thirdly: Most people don’t know how to drill an 80-degree hole. Most drills have attachments that do not require a milling machine and many accessories. It is 100% better to buy a drill than to use a router or other bits. The best way to get the job done is to buy a drill instead of a router.

FAQs on Best Drill Press for 80 Lower

Do you need a drill press for 80 lower?

Of course, if you want to finish your 80 percent lower, you’ll need to invest in a drill press. Although a drill press was explicitly intended for milling, gently milling an 80% lower can be done responsibly. To finish the receiver, all that is required is some “drill” milling to polish the floor and walls. With a drill press and vertically drilled holes and cuts, you can substantially finish your lower.

What machine is required on an 80 lower?

Drills are the best way to drill the required holes in the 80s base. But you will need a lot of tools to complete the styling process for the lower 80s. With the right tools selected, your project will run smoothly. Many additional tools make editing even more accessible. But you will need a drill or grinder, engine oil for lubrication, and a vise to hold the jig at 80%.

Can you finish an 80 lower with a hand drill?

Probably, Yes. But I would recommend the 80% Arms standard used by the router. It’s simple, and you get a well-made base. That being said, you can use a hand drill for the starting holes and a router with a final grinder to finish them. Its shape is designed to make bats victims, but it also handles QD victims just fine with a bit of manipulation.

Who can mill my 80% lower?

You can! In addition, no processing experience is required to bring our receivers up to 80% lower. All you need is a drill, a few parts and cutters, and a mold for 80% of the weapon. You can also use routers and rabble instead, but they will not perform as well. Follow the instructions provided with your kit and avoid some errors to finish your 80% lower.

Can you mill an 80 lower without a jig?

Sure, you can end up 80% lower without a jig, but it will take more effort, and sometimes until you get it. Even something as simple as a cheap drill may go a long way towards achieving decent results. As others have noted, artisans in some countries make weapons by hand, but I believe it will take a lot of practice to get it right. Buying the correct tools is probably less expensive than potentially throwing away a bunch of failed 80 percent lowers.

Take the Best Drill Press for 80% Lower

The best drill Press for 80 lower is always a handy tool for 80-degree holes. So, it has been necessary for everyone to find the best one. I hope from these best five you can choose one for you. For top features at a reasonable price, you can go with the WEN 4208T drill press.

If you do small crafting, I will suggest the Small Bench top 80 lower drill press. But you can’t put the other three aside. Choose one according to your need and enjoy drilling!