To drill a hole for an M8 tap, you need a 6.8mm drill bit. This is crucial for achieving the correct thread size.

Drilling the right size hole for an M8 tap is essential for creating precise threads. If the hole is too big, the threads won’t hold; if it’s too small, the tap might break. Knowing the correct size is fundamental to successful projects.

Many DIY enthusiasts and professionals face this challenge. Missteps can lead to wasted materials and effort. In this guide, we’ll explain why the 6. 8mm drill bit is the best choice for an M8 tap. You’ll learn how to avoid common pitfalls and ensure your threads are perfect every time. Let’s dive into the details and make your tapping process smooth and effective.

Credit: www.amazon.sa

Article Summary

Introduction To M8 Tap

Drilling the correct size hole for an M8 tap is crucial for ensuring a secure and efficient fit. Whether you are a DIY enthusiast or a professional, understanding the specifics of an M8 tap can significantly improve your projects. Let’s delve into what an M8 tap is and its common uses.

What Is An M8 Tap?

An M8 tap is a tool used to cut threads inside a hole, ensuring that a screw or bolt can be securely inserted. The “M8” refers to the metric diameter of the tap, which is 8 millimeters. The tap creates internal threads that match the external threads of an M8 screw or bolt.

Using the correct tap size is vital for the strength and durability of the connection. An M8 tap comes in different thread pitches, so knowing the specific pitch you need is also essential.

Common Uses Of M8 Tap

M8 taps are commonly used in automotive repairs, construction, and metal fabrication. They are perfect for creating threads in metals, plastics, and even wood.

Imagine needing to secure a component in an engine block or setting up a metal frame for a piece of furniture. In these scenarios, an M8 tap would be your go-to tool. The threads it creates ensure that the screws or bolts fit snugly and hold the components together securely.

Have you ever faced a situation where a screw wouldn’t fit properly, and you had to redo the entire setup? Using the right tap size, like the M8, prevents such issues and saves you time.

Understanding the importance and functionality of an M8 tap can make a world of difference in your projects. So, the next time you reach for your toolbox, you’ll know exactly why that M8 tap is essential.

Importance Of Correct Hole Size

Ensuring the correct hole size for an M8 tap is crucial. It affects the quality of the threads and the longevity of the tapped hole. Incorrect hole sizes can lead to poor thread formation and potential damage.

Using the right drill size ensures a perfect fit for the M8 tap. This helps in creating strong and durable threads. The correct hole size also reduces the risk of tap breakage.

Impact On Thread Quality

The quality of the threads depends on the initial hole size. A hole that’s too small can create tight threads. This makes inserting bolts difficult.

A too-large hole can result in loose threads. Loose threads can lead to weak joints. Accurate hole size ensures optimal thread engagement.

Avoiding Damage

Drilling the correct hole size prevents tap damage. A hole that’s too small puts extra stress on the tap. This can cause the tap to break.

A broken tap can damage the workpiece. It can also be difficult to remove. Using the right drill size minimizes these risks.

Determining Hole Size

Determining the correct hole size for an M8 tap is crucial. It ensures a proper fit and secure fastening. This section will guide you on how to determine the right hole size.

Standard Measurements

For an M8 tap, the standard drill size is 6.8mm. This size is derived from the thread pitch and diameter. Always use a precise caliper to measure.

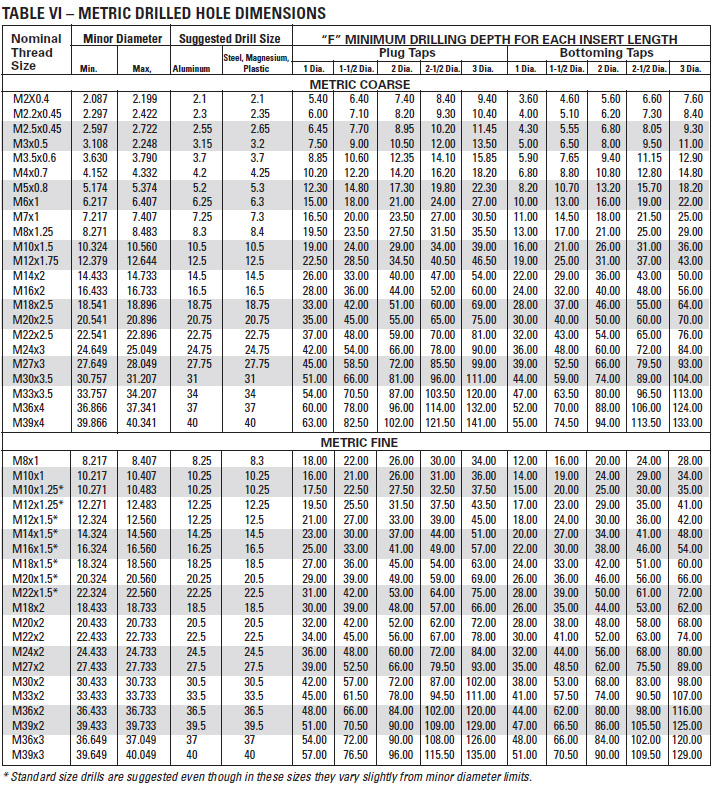

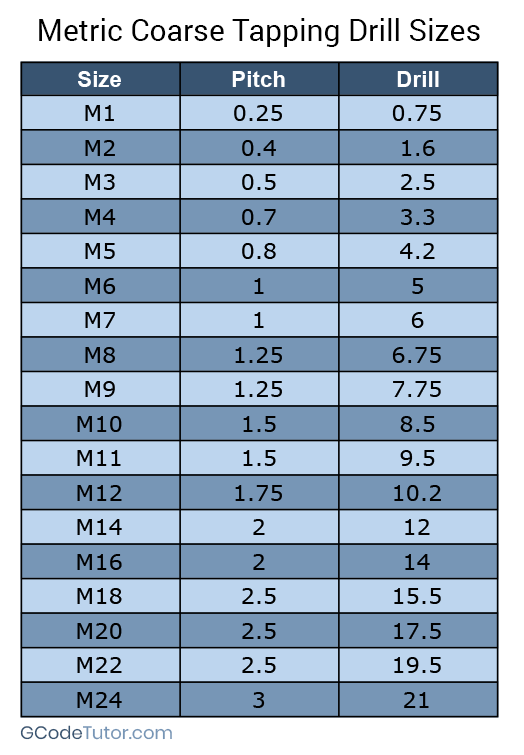

Using Tap Drill Charts

Tap drill charts are helpful tools. They list the correct drill sizes for various taps. For an M8 tap, check the chart for the recommended size. This ensures accuracy and prevents mistakes.

Credit: www.noblefix.com

Tools Required

For drilling a hole for an M8 tap, use a 6. 8mm drill bit. Ensure precise measurement for a proper fit.

When drilling a hole for an M8 tap, having the right tools can make the task much easier and ensure precision. With the correct drill bits and measuring instruments, you can achieve the perfect hole size and depth for your M8 tap. Let’s explore the essential tools required for this process.Drill Bits

Choosing the right drill bit is crucial. For an M8 tap, you need a 6.8mm drill bit. This ensures the hole is appropriately sized for the tap to create threads without damaging the material. You can use high-speed steel (HSS) drill bits for general-purpose drilling. If you’re working with tougher materials like stainless steel, consider cobalt or carbide drill bits. Don’t forget to check the sharpness of your drill bit. A dull bit can lead to inaccurate holes and damage to the material.Measuring Instruments

Accurate measurements are vital for drilling the perfect hole. Use a caliper to measure the drill bit’s diameter and ensure it matches the required 6.8mm. A depth gauge can help you ensure the hole is drilled to the correct depth. This is particularly important if the hole needs to be a specific depth for the M8 tap. Marking tools such as a center punch can help you start the hole in the correct location. This prevents the drill bit from wandering and ensures precision. Have you ever drilled a hole only to find out it’s slightly off? Using the right measuring instruments can prevent this frustrating experience. Remember, precision tools not only make the job easier but also improve your results. So, get your drill bits and measuring instruments ready before you start drilling for your M8 tap.Step-by-step Drilling Process

Drilling the perfect hole for an M8 tap can seem daunting, but with the right steps, it’s manageable. Whether you’re working on a DIY project or a professional task, a clear process ensures precision. Below, we break down the step-by-step drilling process into manageable parts.

Preparing The Material

First, gather your tools. You’ll need a drill, an M8 tap, a tap wrench, and the correct drill bit. For an M8 tap, a 6.8mm drill bit is ideal.

Secure the material you are drilling into. Use clamps to hold the material in place. This prevents movement and ensures accuracy.

Mark the spot where you need to drill. Use a center punch to create a small dent. This guides the drill bit and prevents it from slipping.

Drilling The Hole

Attach the 6.8mm drill bit to your drill. Ensure it’s tightly secured to avoid any wobbling.

Start drilling at a slow speed. This gives you more control and reduces the risk of errors. Steadily increase the speed as you go deeper.

Keep the drill perpendicular to the material. This ensures that the hole is straight and correctly aligned.

Once you have drilled the hole, clean it thoroughly. Remove any debris or shavings. This keeps the hole clear for the tapping process.

Now, you are ready to tap the hole. Insert the M8 tap into the hole and begin threading. Use a tap wrench for better control. Turn the tap slowly and steadily. This will create clean and precise threads.

Drilling for an M8 tap may seem intricate, but breaking it down makes it achievable. Have you ever faced challenges while drilling? Share your experiences and insights in the comments below!

Credit: gcodetutor.com

Testing The Hole

Before you start tapping an M8 thread, it’s crucial to test the hole you’ve drilled. Ensuring the hole size is accurate will help you avoid future issues. Let’s look at some practical steps for testing the hole.

Ensuring Precision

Precision is key. Use a caliper to measure the diameter of the hole. It should be 6.8mm for an M8 tap.

Double-check your drill bit size before drilling. An incorrect bit size can throw off your entire project.

Drilling a test hole in a scrap piece of material can save you from making mistakes on your final piece. Always test first.

Checking For Errors

After drilling, inspect the hole for any irregularities. Look for burrs or uneven edges.

A clean, smooth hole ensures a better threading process. Use a deburring tool if needed.

If the hole isn’t perfect, it could mean trouble when you tap. Correct any issues before moving forward.

Have you ever had a tap break because of an imperfect hole? Share your experiences in the comments below. Your insights could help others avoid similar pitfalls.

Common Mistakes

Drilling holes for an M8 tap can be tricky. Many people make mistakes that affect the final result. These mistakes can lead to improper threading or damaged tools. Understanding these common errors can help you avoid them.

Incorrect Drill Size

Using the wrong drill size is a common mistake. The hole size for an M8 tap should be precise. If the hole is too small, the tap might break. If the hole is too large, the threads won’t hold well. Always use a 6.8 mm drill bit for M8 taps.

Skipping Measurements

Skipping measurements is another error. Some people guess the hole size instead of measuring. This guesswork leads to mistakes. Accurate measurements ensure the right hole size. Use a caliper to measure the drill bit and hole size.

Tips For Successful Drilling

Drill a 6. 8mm hole for an M8 tap. This ensures precise threading and a firm fit. Accurate hole size is crucial for successful drilling.

Drilling the perfect hole for an M8 tap can be challenging, but with the right approach, it becomes much easier. Here are some tips for successful drilling that will help you get the job done right.Maintaining Equipment

Properly maintained equipment is crucial for successful drilling. Ensure your drill bits are sharp and clean. Dull bits can make drilling difficult and result in an inaccurate hole size. Regularly check your drilling machine for any mechanical issues. Lubricate moving parts frequently. This keeps your equipment running smoothly and prevents overheating. You don’t want your drill to break down in the middle of a job. Keep your workspace clean and organized. This helps prevent accidents and ensures you can quickly find the tools you need.Practicing Technique

Practicing your drilling technique will improve your accuracy. Start with scrap materials to get a feel for the drill and the material you’re working on. This helps you understand the pressure needed and the speed required. Use a center punch to mark the spot where you want to drill. This prevents the bit from slipping and ensures precision. Consider your posture and grip. Stand steadily and hold the drill firmly to maintain control. A shaky hand can lead to an uneven hole. Remember, patience is key. Rushing can lead to mistakes. Take your time and focus on each step of the process. Drilling the correct size hole for an M8 tap requires attention to detail and practice. What challenges have you faced while drilling? Share your experiences and tips to make this process smoother for everyone.Frequently Asked Questions

What Size Drill Do I Need For A M8 Tap?

Use a 6. 8mm drill bit for an M8 tap. This ensures proper thread engagement and hole size.

What Size Hole For M8 Thread?

For an M8 thread, the recommended hole size is 6. 75 mm. This ensures proper threading and fit.

What Size Drill Bit For M8x1 25 Tap?

Use a 6. 8mm drill bit for an M8x1. 25 tap. This size ensures proper threading and fit.

What Size Pilot Hole For M8?

For an M8 bolt, the recommended pilot hole size is 6. 8mm for standard threading. This ensures a proper fit.

Conclusion

Knowing the right drill size for an M8 tap is essential. It ensures accurate threading. Use a 6. 8mm drill bit for best results. This helps create clean, precise threads. Avoid mistakes by double-checking measurements. Proper tools make a big difference.

Follow these tips for successful drilling. Happy tapping!