To drill a hole for a 1/4 tap, you need a specific size. The correct hole size ensures the tap threads properly and securely.

Drilling the right hole size for a 1/4 tap is crucial for successful threading. If the hole is too small, the tap may break or bind. If too large, the threads won’t hold. Understanding tap drill sizes can save time and prevent errors.

This guide will help you determine the exact hole size for a 1/4 tap. Whether you’re a beginner or an experienced DIYer, knowing the correct drill size is essential. Let’s dive in and find out the perfect drill size for your 1/4 tap, ensuring a smooth and efficient project.

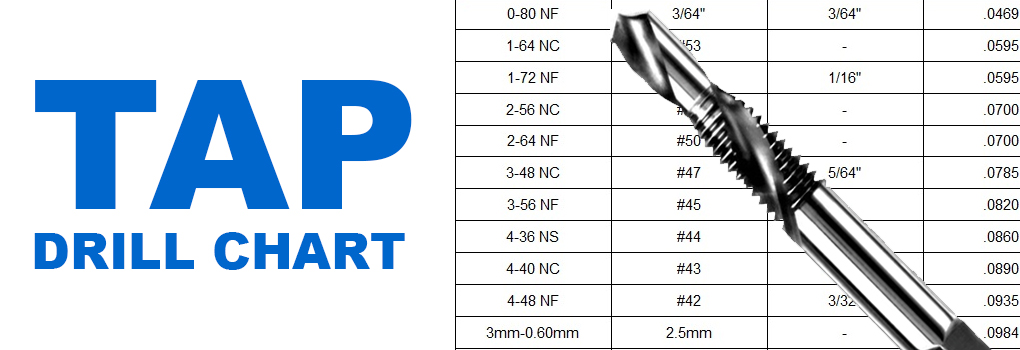

Credit: www.fastenere.com

Article Summary

Understanding Tap Sizes

Drilling the correct hole size for a 1/4 tap is crucial. A 7/32 inch drill bit works best for this tap size. Ensures proper threading and secure fit.

### Understanding Tap Sizes Understanding tap sizes is crucial for anyone who works with machinery or does DIY projects. Have you ever wondered why certain screws just don’t fit properly? Or why you end up stripping a screw thread? It all comes down to using the correct tap size. ### Definition of Tap Sizes Tap sizes refer to the dimensions of a tap, which is a tool used to cut threads inside a hole. These sizes are determined by the diameter and the pitch of the thread. For example, a 1/4 tap has a nominal diameter of 0.25 inches. It’s essential to know these measurements to ensure a secure fit for bolts and screws. ### Why Tap Sizes Matter Using the correct tap size ensures that your screw threads are cut accurately. This prevents issues like loose fittings or stripped threads. Imagine you’re assembling a piece of furniture and the screws keep turning without tightening. That’s likely because the hole was either too big or too small for the tap size. By using the right tap size, you avoid these headaches. Having the right tap size also enhances the durability of your projects. The correct fit ensures that everything holds together well, which means less maintenance and more peace of mind. So, what size hole should you drill for a 1/4 tap? The answer lies in understanding the tap size and its importance. Ready to get your hands dirty? Let’s get drilling!

Credit: www.tannerbolt.com

Tools Needed

For a 1/4 tap, you need a drill bit that is 7/32 inches. Ensure precision by using a caliper to verify size.

When drilling a hole for a 1/4 tap, the tools you use can make all the difference. The right tools will ensure accuracy, prevent damage, and make the job easier. Let’s break down the essential tools needed for this task. ### Drill Bits Choosing the right drill bit is crucial. For a 1/4 tap, you typically need a #7 drill bit. This size provides the correct pilot hole for the tap to cut precise threads. Keep a set of quality drill bits on hand. Cheap bits can dull quickly and make your job harder. I once used an old, dull bit and ended up with a misaligned hole. Lesson learned: always check your bits before starting. ### Measurement Tools Accurate measurements are key to drilling the right size hole. A caliper is your best friend here. It ensures that your drill bit is the correct diameter for the tap. A good ruler or measuring tape also helps. Measure twice, drill once, as they say. Using a center punch to mark your drilling spot can prevent the bit from wandering. This simple tool makes a big difference in precision. Having the right tools not only saves time but also improves the quality of your work. What tools have you found indispensable for drilling and tapping?Steps To Determine Hole Size

Drilling a hole for a 1/4 tap requires precision. Use a 7/32 inch drill bit for the best fit. This ensures the tap cuts threads properly.

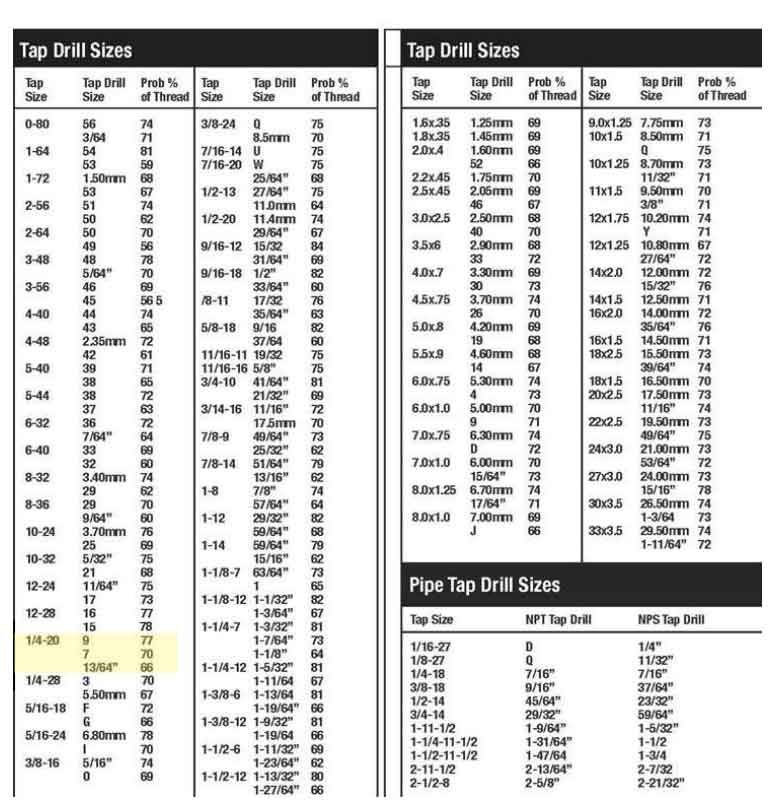

Determining the right hole size for a 1/4 tap is crucial for creating clean, precise threads. The process may seem daunting, but with the right approach, you can achieve perfect results every time. Let’s break down the steps to determine the hole size. ###Reference Charts

Reference charts are a handy tool. They provide a quick and accurate method to find the correct hole size for different tap sizes. Most hardware stores and online resources offer detailed charts. These charts list the recommended drill bit size for various tap sizes. For a 1/4 tap, you’ll typically find suggestions like 7/32″ or 13/64″. Keep one of these charts in your toolbox. It saves time and ensures you’re using the correct drill bit. ###Manual Calculation

Sometimes, you might not have access to a chart. In such cases, manual calculation is your friend. Use the formula: Drill Size = Tap Size – Thread Pitch. For instance, if you have a 1/4-20 tap, subtract the thread pitch (0.05) from the tap size (0.25). This gives you a drill size of 0.20 inches. Converting this to a fraction, you get approximately 13/64″. This method is reliable, but double-check your calculations. Understanding these methods is key to success. Have you faced challenges finding the right hole size? Share your experiences in the comments!

Credit: mechanics.stackexchange.com

Drilling Techniques

To drill a hole for a 1/4 tap, use a 7/32 inch drill bit. This ensures a proper fit for threading. Accurate measurements lead to successful tapping.

Drilling Techniques Drilling a precise hole for a 1/4 tap is crucial for achieving a strong and reliable thread. It’s not just about the size of the hole; it’s about the technique used to drill it.Safety Precautions

Before you start drilling, ensure your workspace is safe. Wear safety goggles to protect your eyes from flying debris. Use gloves to get a good grip and avoid accidents. Secure the material you’re drilling into using clamps or a vise. This will prevent it from moving and causing errors or injury. Ensure your drill bits are sharp and in good condition. Dull bits can slip or break, creating hazards.Drilling Best Practices

Measure twice, drill once. Always double-check your measurements before drilling. Accuracy is key for a 1/4 tap hole. Select the correct drill bit size. For a 1/4 tap, a 7/32” drill bit is typically recommended. This size creates the perfect hole diameter for threading. Use a center punch to mark the spot where you’ll drill. This prevents the drill bit from wandering off course. Drill at a slow and steady speed. Rushing can lead to mistakes and uneven holes. Take your time to ensure precision. Keep your drill perpendicular to the work surface. An angled hole can compromise the integrity of the thread. Regularly remove shavings from the hole. This keeps the workspace clear and helps maintain the drill bit’s efficiency. Have you ever drilled a hole that wasn’t accurate? It’s frustrating, right? Using these techniques can save you time and ensure perfect results every time. Remember, practice makes perfect. If you’re new to drilling, start with scrap material. This allows you to refine your technique without risking your project. What other drilling challenges have you faced? Share your experiences and tips below. Let’s learn from each other’s mistakes and successes.Common Mistakes

Drilling holes for a 1/4 tap is a common task in many projects. Yet, many make simple mistakes that can lead to problems. These mistakes are easy to avoid with a bit of care and knowledge. Understanding the common mistakes can save time and effort.

Avoiding Overdrilling

Overdrilling happens when the hole is too large. This can lead to weak threads. Weak threads cannot hold screws or bolts well. To avoid this, always use a drill bit of the right size. Check the tap drill size chart. Follow the chart to select the correct bit.

Using the wrong bit can cause problems. It can also damage the material. Always double-check before drilling. It is a simple step that can prevent many issues.

Ensuring Correct Alignment

Correct alignment is crucial for a good tap. If the hole is not straight, the threads will be uneven. Uneven threads can cause the screw to fit poorly. Use a drill press for the best results. A drill press keeps the drill straight. If you use a hand drill, be extra careful. Take your time to ensure a straight hole.

Using a guide can help. A guide keeps the drill bit aligned. It is a useful tool for beginners. Even experts use guides for precision work. Proper alignment makes the tapping process smoother and more effective.

Troubleshooting Issues

Drilling the correct hole size for a 1/4 tap can sometimes be tricky. Mistakes happen, and you might end up with a hole that’s too big or too small. Knowing how to troubleshoot these issues is essential. It ensures your projects are successful and frustration-free.

Fixing Incorrect Hole Sizes

Incorrect hole sizes can cause problems. If the hole is too big, the tap won’t grip properly. If it’s too small, the tap might break. To fix a hole that’s too big, consider using a thread insert. This can help restore the proper size. For a hole that’s too small, re-drilling is necessary. Use the correct drill bit size for the 1/4 tap.

Re-drilling Tips

Re-drilling a hole requires precision. Start by ensuring you have the right drill bit. Secure the material firmly to avoid movement. Use a slower drill speed to maintain control. Apply steady pressure and avoid forcing the bit. This reduces the risk of breaking the tap. Re-check the hole size after drilling to ensure it’s correct. Always wear safety gear to protect yourself during the process.

Frequently Asked Questions

What Size Drill Bit Do I Need For A 1 4 Tap?

For a 1/4 tap, you need a 7/32 drill bit. Ensure accuracy for a proper fit and threading.

What Size Hole For A 1/4 Thread?

Drill a 7/32 inch hole for a 1/4-20 thread. This provides the best fit for threading.

What Is The Tap Drill Size For A 1/4-20 Unc?

The tap drill size for a 1/4-20 UNC thread is 13/64 inches or 5. 16 mm.

What Size Hole To Drill For 1/4 Npt Tap?

Drill a 7/16 inch hole for a 1/4 NPT tap. This ensures proper thread engagement and fit.

Conclusion

Choosing the correct drill size is essential for a 1/4 tap. A 7/32 inch drill bit works best for this purpose. This ensures a perfect fit and prevents damage. Always double-check measurements before drilling. This step helps avoid costly mistakes.

Using the right tools and measurements makes the job easier. Remember, precision is key for successful tapping. Now, you’re ready to drill with confidence. Accurate drilling ensures a strong, secure fit. Happy drilling!