So, you’ve got your hands on a 5/16″ tap, and ready to embark on a drilling project, right? Embarking on a drilling project can be both exciting and daunting.

Also it can be a bit confusing when it comes to selecting the right size hole for a 5/16″ tap. And you may think that What Size Hole To Drill For 5/16 Tap?

Precision is key, and understanding the tap sizing and drill bit selection is vital for success. And in this friendly guide, I will unravel the mysteries of tap sizing. Also, I’ve shared some formulas for calculating tap drill size And more. So let’s go!

What Size Drill Bit for 5/16″ Tap?

Selecting the appropriate drill bit size for a 5/16″ tap is critical to ensure precise and secure threading in your drilling project. In this guide, we will explore the intricacies of determining the correct drill bit size for a 5/16″ tap.

The 5/16″ tap refers to its thread size, indicating the external diameter of the threads. To determine the right drill bit size for this tap, a specific calculation method comes into play. For a 5/16″ tap, where the external diameter is 0.3125 inches, this calculation results in the ideal drill bit size.

After performing the calculation, the recommended drill bit size for a 5/16″ tap is 17/64″ or 0.2656 inches. Using this precise drill bit size guarantees a snug fit for the tap, enabling the creation of threads with the perfect depth and grip.

When drilling for a 5/16″ tap, it is essential to adhere to this recommended drill bit size to avoid issues such as misaligned or weak threads. Using the correct drill bit ensures that the tap can cut threads accurately and securely, leading to a successful drilling project.

How Tap Sizing Works for 5/16″ Tap?

Tap sizing refers to the process of matching the tap’s external diameter with the appropriate hole size. It allows for the creation of precise and secure threads. Let’s delve into the intricacies of tap sizing for a 5/16″ tap on this essential aspect of drilling.

The 5/16″ designation in a tap’s size indicates the thread’s external diameter. When selecting a tap for your project, it’s crucial to comprehend this measurement. The challenge lies in drilling a hole that perfectly accommodates this external diameter.

To achieve this balance, it’s essential to calculate the tap drill size accurately. This involves determining the pitch diameter, which is the major diameter minus the thread height. By subtracting the pitch diameter from the tap’s external diameter, you arrive at the precise measurement for the drill bit size.

In the case of a 5/16″ tap, where the external diameter is 0.3125 inches, the calculation for the ideal drill bit size is performed as follows:

Drill Bit Size=External Diameter of Tap−Pitch Diameter

Drill Bit Size=0.3125inches−(Major Diameter−Thread Height)

This calculation ensures that the drill hole provides enough space for the tap to fit securely without play, preventing wobbling and facilitating precise threading. Using an incorrectly sized hole can result in damaged threads, weakening the connection and potentially compromising the entire project.

How Do You Calculate Tap Drill Size for 5/16″?

Calculating the tap drill size for a 5/16″ tap involves a precise formula that ensures the drilled hole accommodates the tap securely, allowing for accurate and reliable threading.

Here’s a step-by-step guide on how to calculate the tap drill size for a 5/16″ tap:

Understand the Terminology:

External Diameter of Tap (D): The given tap size, in this case, 5/16″, needs to be converted to decimal form. For a 5/16″ tap, the decimal equivalent is 0.3125 inches.

Pitch Diameter (PD): This is the major diameter (the widest part of the thread) minus the thread height. It’s a critical measurement for accurate tap sizing.

Calculate the Pitch Diameter (PD):

The thread height can be calculated by dividing the difference between the major diameter and the minor diameter by 2. For a standard 5/16″ UNC (Unified National Coarse) thread, the major diameter is 0.3125 inches, and the minor diameter is 0.2595 inches.

Thread Height = (0.3125 – 0.2595) / 2 = 0.0265 inches.

Pitch Diameter (PD) = Major Diameter – Thread Height = 0.3125 – 0.0265 = 0.286 inches.

Use the Formula:

Tap Drill Size = External Diameter of Tap (D) – Pitch Diameter (PD).

For a 5/16″ tap: Tap Drill Size = 0.3125 – 0.286 = 0.0265 inches.

Therefore, the calculated tap drill size for a 5/16″ tap is 17/64″ or approximately 0.2656 inches. Using this precise drill bit size ensures that the tap fits snugly, creating threads with the right depth and grip.

This accuracy is crucial for achieving strong, reliable connections without damaging the material being threaded. Always double-check your calculations and use the appropriate tools to guarantee the success of your drilling projects.

Get Drilling with a 5/16″ Tap

Getting started with your 5/16″ tap requires careful preparation and precision. Here’s a step-by-step guide to help you get drilling confidently and effectively:

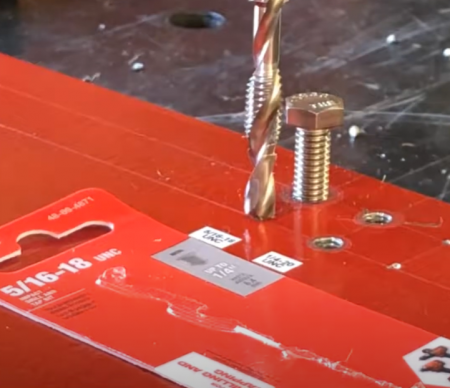

- Gather Your Tools:

Ensure you have your 5/16″ tap, the corresponding 17/64″ or 0.2656 inches drill bit, a reliable drill machine, safety glasses, and appropriate lubricant (cutting oil) for smoother drilling.

- Mark the Drilling Spot:

Use a center punch to mark the exact spot where you want to create the threaded hole. This small indentation will act as a guide for your drill bit, ensuring accuracy.

- Secure Your Material:

If you’re drilling into a material such as metal or wood, secure it firmly in place using clamps or a vice. This prevents unnecessary movement during drilling, ensuring a straight and precise hole.

- Start Drilling:

Insert the 17/64″ drill bit into your drill machine. Put on your safety glasses to protect your eyes from debris. Start the drill at a slow speed. Apply steady, even pressure as you begin drilling into the marked spot. Keep the drill perpendicular to the material surface to ensure the hole is straight.

- Use Lubricant

While drilling, periodically apply cutting oil or lubricant to the drill bit. This helps dissipate heat and prolongs the life of your drill bit. It also makes the drilling process smoother.

- Drill to the Desired Depth

Drill the hole to the required depth. Pay attention to depth markings on the drill bit or use a depth stop on your drill machine to avoid drilling too deep.

- Tapping Process

Once the hole is drilled, remove the 17/64″ drill bit from the machine.

Insert your 5/16″ tap into the drilled hole. Make sure it sits securely. Turn the tap handle slowly and steadily clockwise. Feel the tap biting into the material. Periodically rotate the tap counterclockwise to break the chips and clear debris. Continue tapping until the desired depth is achieved or the tap reaches the bottom of the hole.

- Test the Threads

After tapping, carefully remove the tap from the hole. Test the threads by inserting a bolt or screw. The threads should engage smoothly without any wobbling or resistance.

- Clean and Finish

Clean the drilled hole and the tap to remove any debris or cutting oil residue.

Your drilling process is complete! You’ve successfully created precise threads for your specific project.

Remember, patience and attention to detail are key when working with a 5/16″ tap. By following these steps and using the correct tools, you can achieve professional results in your drilling endeavors. Happy drilling!

Final Words

As I conclude our exploration of what size hole to drill for a 5/16 tap, it’s evident that the art of drilling is as much about science as it is about skill. Armed with the right information, calculations, and tools, you can transform raw materials into finely threaded masterpieces.

So, whether you’re crafting, building, or repairing, remember the importance of accurate drilling. It’s a testament to your attention to detail and commitment to quality. The perfect hole for your 5/16″ tap is not just a drill away; it’s a testament to your expertise and dedication to precision. Happy drilling!