What size drill bit for a 10 screw? It’s a simple question, but using the wrong size can ruin your project in seconds. I’ve been there—and I’ll help you get it right the first time.

Let me be honest—I’ve ruined more wood than I care to admit by picking the wrong drill bit. If you’ve ever split wood or stripped a screw head, you’re in good company. Figuring out the right size drill bit for a #10 screw can feel like a puzzle, especially when you’re just trying to hang shelves or fix something fast.

But don’t worry—I’ve got you covered. I’m going to break it all down in a way that’s easy to understand, based on both personal trial-and-error and some solid technical basics.

Article Summary

- What’s a #10 Screw Anyway?

- Why Drill Bit Size Matters (And What Happens If You Guess)

- So, What Size Drill Bit for a #10 Screw?

- Pilot Holes: What They Are and Why I Always Drill Them

- Matching Drill Bits to Materials

- Wood Screws vs Machine Screws: Don’t Mix Them Up

- A Drill Bit Size Chart You’ll Want to Bookmark

- Step-by-Step: How I Choose the Right Drill Bit for a #10 Screw

- A Real-Life Example: Hanging a Wall Shelf

- What If I Don’t Have the Exact Drill Bit?

- Pro Tips I’ve Picked Up Over Time

- Suggested Tools and Accessories

- What Size Drill Bit for a #10 Screw in Metal?

- What Size Drill Bit for #10 Screw in Fiberglass?

- FAQs About #10 Screw Drill Bit Sizes

- Final Thoughts: Keep It Simple and Test First

What’s a #10 Screw Anyway?

Before we jump into drill bits, let’s clear up what a “#10 screw” actually means. I used to think the number was about the length. Nope!

A Quick Breakdown:

- #10 refers to the diameter—not the length—of the screw.

- A #10 screw has a major diameter of 0.190 inches (about 4.83 mm).

- It’s commonly used in wood, metal, and plastic projects.

I usually reach for #10 screws when I’m mounting something a bit heavier—like curtain rods, shelves, or even drawer hardware.

Why Drill Bit Size Matters (And What Happens If You Guess)

I once used a bit that was too small and ended up snapping the screw head right off. Another time, I went too big and the screw barely gripped anything. Here’s why drill bit size matters:

The Problems I’ve Faced:

- Too small: Splits wood, hard to screw in, and risks breaking screws.

- Too big: Screw doesn’t grip, things wobble or fall off.

- Just right: The screw slides in nicely and holds firm.

That’s why picking the right drill bit is more than a detail—it’s what holds your project together.

So, What Size Drill Bit for a #10 Screw?

This is the question, right? The answer depends on whether you’re drilling a pilot hole, a clearance hole, or tapping into metal.

Let’s break it down:

| Application | Drill Bit Size | Notes |

|---|---|---|

| Pilot Hole (Softwood) | 7/64″ (0.109″) | Helps avoid splitting and gives strong grip |

| Pilot Hole (Hardwood) | 1/8″ (0.125″) | Slightly larger for dense materials |

| Clearance Hole | 13/64″ (0.203″) | Hole is just big enough for the screw to pass through |

| Tapping into Metal | No. 21 Drill Bit (0.159″) | Used when threading a hole for a #10-32 machine screw |

Pilot Holes: What They Are and Why I Always Drill Them

If I had a dollar for every time I skipped a pilot hole and cracked the wood, I’d probably own better tools by now.

A Pilot Hole Is…

A small pre-drilled hole that guides the screw and reduces the chance of splitting wood.

Why I Drill Pilot Holes:

- Prevents wood from cracking

- Makes driving screws easier

- Extends screw and bit life

Think of a pilot hole like rolling out the red carpet for your screw—it’s going to make everything smoother.

Matching Drill Bits to Materials

Depending on what you’re drilling into, the bit size might change a little.

For Wood Projects:

Here’s what I usually do:

| Wood Type | #10 Screw Drill Bit Size | Screw Length Tip |

|---|---|---|

| Softwood | 7/64″ | Use screws at least 1.5x the thickness of material |

| Hardwood | 1/8″ | Use wax or soap to ease driving |

For Metal Projects:

This part scared me at first, but here’s a shortcut that’s helped me:

- Use a No. 21 drill bit for #10-32 machine screws.

- Always wear safety glasses—metal shavings are no joke.

- Go slow and use cutting oil to keep things cool.

Wood Screws vs Machine Screws: Don’t Mix Them Up

This tripped me up early on. A #10 screw in wood is not the same as a #10-32 screw for metal.

How I Tell Them Apart:

- Wood Screws: Coarse threads, pointed tips

- Machine Screws: Fine threads, blunt tips, used with nuts or threaded holes

Always check the screw package. If it says “#10 x 1-1/2”, it’s likely for wood. If it says “#10-32”, it’s a machine screw.

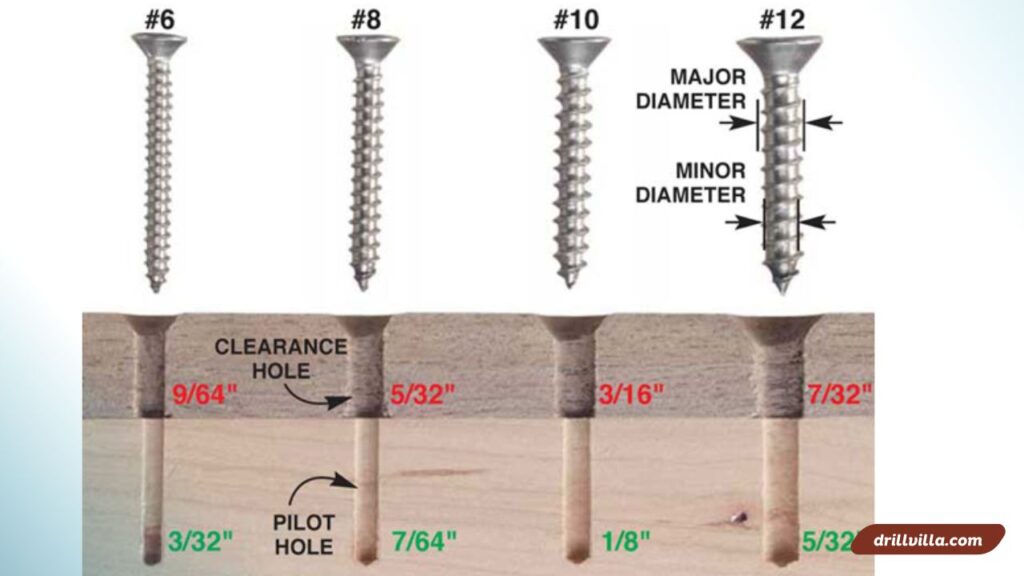

A Drill Bit Size Chart You’ll Want to Bookmark

Here’s a chart I keep taped up in my workshop. It saves time and headaches.

| Screw Size | Pilot Bit (Softwood) | Pilot Bit (Hardwood) | Clearance Hole | Tapping Drill (Metal) |

|---|---|---|---|---|

| #6 | 3/32″ | 7/64″ | 9/64″ | No. 36 (0.106″) |

| #8 | 7/64″ | 1/8″ | 11/64″ | No. 29 (0.136″) |

| #10 | 7/64″ | 1/8″ | 13/64″ | No. 21 (0.159″) |

| #12 | 1/8″ | 9/64″ | 15/64″ | No. 16 (0.177″) |

Step-by-Step: How I Choose the Right Drill Bit for a #10 Screw

I’ve got a little process I follow every time:

- Identify the screw type (wood or machine screw?)

- Measure your material (soft or hardwood? thick or thin?)

- Pick the right bit from the chart

- Test it on scrap wood—I always drill a test hole first

- Drill slow and steady—let the bit do the work

A Real-Life Example: Hanging a Wall Shelf

Let me share a quick story.

I was hanging a floating shelf for my books. I used #10 x 2” screws and soft pine studs. At first, I grabbed a 1/8” bit, but it felt too tight. I switched to 7/64” and bam—perfect fit.

That small change made the screws glide in like butter, no split wood, and the shelf has been holding strong for over two years.

What If I Don’t Have the Exact Drill Bit?

Been there, friend.

Here’s What I Do:

- Go slightly smaller: You can always make a hole bigger, but not smaller.

- Twist bit + test fit: Try screwing in by hand to check resistance.

- Use a drill stop: Helps control depth if you’re worried about going too far.

In a pinch, I’ve even wrapped masking tape around a smaller bit to “fake” a thicker size—but only for quick fixes.

Pro Tips I’ve Picked Up Over Time

These little tips have saved me hours:

- Label your drill bits with a silver marker. Saves so much guesswork.

- Use a drill bit gauge (cheap and handy!).

- Buy a bit set that includes fractional, number, and letter sizes—especially if you work with metal.

Suggested Tools and Accessories

Here are a few things I personally use and love:

| Tool | Why I Love It |

|---|---|

| Titanium Drill Bit Set | Handles hardwood and soft metals |

| Magnetic Bit Holder | Makes changing bits way easier |

| Drill Stop Collar | Prevents drilling too deep |

| Digital Caliper | Great for double-checking screw diameters |

| Pilot Hole Centering Punch | Perfect for precise screw placement |

What Size Drill Bit for a #10 Screw in Metal?

I remember the first time I had to drill into metal for a #10 screw. I was fixing a metal bracket on my trailer, and I didn’t want to mess it up. Drilling into metal feels intense—one wrong move and you’ve got a stripped hole or a broken bit.

So, what size drill bit for a 10 screw in metal? Here’s the answer I wish someone had told me right away:

- If it’s a sheet metal screw going into soft metal (like aluminum):

Use a #20 drill bit, which is about 0.161 inches. - For harder metals (like steel):

I go with a #21 drill bit (around 0.159 inches). It gives just a bit more grip.

These drill bit sizes are perfect for tapping threads, meaning the screw cuts its own threads into the hole. I like to use a bit of cutting oil while drilling—it keeps the bit cooler and the hole cleaner.

Here’s a Quick Table:

| Screw Type | Material | Drill Bit Size | Drill Bit # | Decimal (Inches) |

|---|---|---|---|---|

| #10 screw | Aluminum | 0.161″ | #20 | 0.1610 |

| #10 screw | Steel | 0.159″ | #21 | 0.1590 |

One tip from experience: don’t push too hard. Let the drill do the work. And if the bit starts smoking, stop and add more oil. That saved me from burning through my bits more times than I can count.

What Size Drill Bit for #10 Screw in Fiberglass?

Drilling fiberglass gave me a whole different kind of anxiety. It’s not like wood or metal. It splinters if you’re not careful. I learned the hard way while installing rod holders on my boat. My first hole was a mess—cracked edges and all.

So, what size drill bit for a 10 screw in fiberglass?

Here’s what worked best for me:

- Use a 1/8-inch pilot hole first to avoid splintering.

- Then drill with a 5/32-inch bit (0.15625 inches) for the final hole.

This size lets the #10 screw grab the fiberglass securely without cracking it. And if the screw is going into a backing block (like marine plywood), the pilot hole helps guide everything straight.

My Fiberglass Drilling Tips:

- Tape the surface where you’ll drill. Painter’s tape works well. It keeps the surface from chipping.

- Go slow. High speed will burn the fiberglass and mess up the edges.

- Don’t overtighten the screw. Fiberglass hates pressure. Trust me—one good twist too many and you’ll be patching holes.

Quick Reference Table:

| Material | Screw Size | Pilot Hole (in) | Final Drill Bit (in) |

|---|---|---|---|

| Fiberglass | #10 | 1/8″ | 5/32″ |

So next time you’re wondering what size drill bit for a 10 screw in fiberglass, remember—start small, drill slow, and protect the surface.

FAQs About #10 Screw Drill Bit Sizes

Q: Can I use the same drill bit for wood and metal?

A: Technically yes, but it’s better to use bits made for the material. Metal bits are harder and designed for slower speeds.

Q: What if I don’t drill a pilot hole?

A: You risk splitting the wood or snapping the screw—especially in hardwood. I always recommend it.

Q: Is there a universal bit size for a #10 screw?

A: No, it depends on the material and whether you’re doing a pilot or clearance hole. But 7/64″ is a great starting point for softwood pilot holes.

Final Thoughts: Keep It Simple and Test First

The biggest lesson I’ve learned? Don’t overthink it. Start with the size in the chart, drill a test hole in some scrap, and trust your gut.

Choosing the right drill bit size for a #10 screw can feel overwhelming at first, but it becomes second nature once you’ve done it a few times.

If you take one thing away from this guide, let it be this: a 7/64″ bit for softwood is your best buddy, and for hardwood, go up to 1/8″. Keep a cheat sheet nearby, and don’t be afraid to test before you commit.

Your projects (and your stress levels) will thank you.

Know More:

- How Much Does It Cost To Drill A Bowling Ball?

- What Size Drill Bit for 10 Screw

- Are You Supposed To Submerge Powered Orthopedic Drills For Decontamination?

- A 135 Split Point Cobalt Letter Drill Bits?

- How Long Does It Take to Drill a Water Well?

- What Type of Drill Bits Won’t Snap?

- What Are the Best Drill Bits for Stainless Steel?