A drill press is a powerful tool used for drilling precise holes. But what is drill press swing?

Drill press swing is the distance between the spindle center and the column, doubled. Understanding drill press swing is crucial for choosing the right tool. It determines the size of material you can work with. A larger swing means you can drill into larger pieces.

For example, a drill press with a 10-inch swing can drill holes in the center of a 10-inch wide board. Knowing this helps you pick the right drill press for your projects. Stay tuned to learn more about how drill press swing impacts your work and which drill press might be best for you.

:max_bytes(150000):strip_icc()/DB_1892-88aa27e721824b5898c048f63891a2cd.jpg)

Credit: www.woodmagazine.com

Article Summary

Introduction To Drill Press Swing

Understanding the Drill Press Swing is essential for anyone involved in DIY projects. This term often confuses beginners. Yet, it is a key concept in using a drill press effectively. By learning about drill press swing, you can make better tool choices and enhance your work quality.

Definition Of Drill Press Swing

The drill press swing refers to the maximum diameter of a workpiece that can be drilled through its center. It is calculated by doubling the distance from the drill bit to the column of the drill press. For instance, if this distance is 5 inches, the drill press has a swing of 10 inches.

| Distance from Drill Bit to Column | Swing |

|---|---|

| 5 inches | 10 inches |

| 6 inches | 12 inches |

The swing determines the size of the material you can work with. A larger swing means you can work with bigger pieces. This is crucial for certain projects requiring specific dimensions.

Importance In Diy Projects

Understanding the swing of a drill press is vital for DIY enthusiasts. It allows you to choose the right tool for your project. If your project involves large pieces, a drill press with a bigger swing is necessary. This ensures precision and efficiency.

Working with the correct swing size also improves safety. Smaller swings limit the size of the workpiece, preventing overloading. This reduces the risk of accidents and tool damage. Always check the swing before starting a project.

In summary, knowing the drill press swing helps you select the right tool. It also ensures your projects are accurate and safe. This knowledge is fundamental for anyone serious about their DIY work.

Key Components Of A Drill Press

A drill press is a versatile tool used for drilling precise holes. Understanding its key components helps you use it effectively. Let’s explore the main parts of a drill press.

Base And Column

The base is the foundation of the drill press. It provides stability and support. It is usually made of cast iron. The column is attached to the base. It is a vertical metal post. The column supports the head and the table. It ensures accurate vertical alignment.

Table And Spindle

The table is where you place your workpiece. It is adjustable for different heights and angles. The table helps in positioning the material precisely. The spindle holds the drill bit. It rotates to drill holes into the workpiece. The spindle’s speed can be adjusted for different materials. Together, the table and spindle ensure precise and efficient drilling.

Measuring Drill Press Swing

Understanding the drill press swing is vital for precision drilling tasks. The swing of a drill press indicates the maximum distance from the spindle to the column, doubled. This measurement helps determine the size of the workpiece you can handle. Let’s explore how to measure the drill press swing accurately.

Tools Needed

- Measuring Tape or Ruler

- Pen and Paper for Notes

- Drill Press

Step-by-step Guide

- Turn off the drill press and unplug it for safety.

- Locate the spindle, the rotating part that holds the drill bit.

- Find the column, the vertical support structure of the drill press.

- Measure the distance from the spindle to the column using a measuring tape or ruler.

- Record this distance. This is the radius of the drill press swing.

- Double the recorded radius to get the swing measurement.

For example, if the distance from the spindle to the column is 5 inches, the drill press swing is 10 inches. This means your drill press can handle workpieces up to 10 inches in diameter.

Choosing The Right Drill Press

Finding the perfect drill press can be challenging. The drill press swing is an essential factor. It determines the maximum width of the material you can drill. Here’s how to choose the right one for your needs.

Factors To Consider

Consider several factors when choosing a drill press:

- Drill Press Swing: This is the distance between the drill bit and the column. It affects the size of the workpiece.

- Motor Power: More power allows for drilling through harder materials.

- Speed Settings: Variable speeds offer more control and precision.

- Table Size: A larger table provides more support for bigger projects.

- Build Quality: Look for sturdy construction for durability.

Top Brands

Several brands are known for their quality drill presses:

| Brand | Features |

|---|---|

| Jet | High-quality, durable, and versatile. |

| Delta | Reliable with advanced features. |

| WEN | Affordable and user-friendly. |

| Shop Fox | Precision and ease of use. |

Benefits Of Proper Swing Measurement

The benefits of proper swing measurement in a drill press are significant for achieving precision and quality in your projects. By understanding and utilizing the correct swing measurement, you can enhance the accuracy and overall outcome of your work. Let’s delve into the key benefits.

Accuracy In Drilling

A proper swing measurement ensures that the drill bit is centered accurately. This is crucial for precision drilling. The exact positioning of the drill bit helps in creating uniform holes. Misalignment can lead to errors, compromising the integrity of your work.

Accurate drilling is vital in various applications, from woodworking to metalworking. It allows you to maintain consistency across multiple pieces. This consistency is key to professional-quality results.

Enhanced Project Quality

When the swing measurement is correct, it contributes to the overall quality of your projects. Proper alignment ensures that each hole is drilled at the correct angle and depth. This precision minimizes the need for rework, saving time and resources.

High-quality drilling results in cleaner, more precise holes. This not only looks better but also ensures that components fit together perfectly. A well-drilled hole can make the difference between a sturdy, reliable structure and one that is prone to failure.

- Better fit and finish

- Increased structural integrity

- Reduced material waste

By paying attention to swing measurement, you can achieve professional-grade results in your drilling projects. This attention to detail sets apart good work from great work.

Credit: www.homedepot.com

Common Mistakes To Avoid

Understanding drill press swing is crucial for precise drilling. Avoid common mistakes to ensure accurate results. Let’s explore some errors and how to prevent them.

Incorrect Measurements

Measure twice, cut once. This saying applies to drilling too. Incorrect measurements can lead to wasted materials. Always double-check your measurements before drilling.

Use a reliable measuring tool. A ruler or tape measure works well. Ensure you measure from the right starting point. Mistakes often happen when the wrong reference point is used.

Ignoring Swing Importance

The swing of a drill press determines its capacity. Ignoring this can limit your project. Make sure the swing matches the project’s requirements.

Understand the swing range. It’s the distance from the spindle to the support column, doubled. This gives the maximum width of material you can work on.

Choosing the wrong swing means you can’t drill in the center of large workpieces. Plan accordingly to avoid this mistake.

Maintenance Tips For Drill Press

Maintaining a drill press is essential for its long-term performance. Proper care can extend its life and ensure accurate drilling. Here are some key maintenance tips to keep your drill press in top shape.

Regular Cleaning

Regular cleaning of the drill press prevents dust and debris buildup. Accumulated dust can affect the machine’s accuracy and performance. Follow these steps for cleaning:

- Wipe down the surfaces with a soft cloth after each use.

- Use a vacuum to remove dust from hard-to-reach areas.

- Clean the chuck and spindle area frequently.

Keeping the drill press clean ensures smooth operation and reduces wear.

Lubrication And Inspection

Lubrication is crucial for the moving parts of the drill press. Proper lubrication reduces friction and wear. Regular inspection helps identify any potential issues early. Follow these guidelines for lubrication and inspection:

- Check the manufacturer’s manual for recommended lubricants.

- Apply lubricant to the spindle, quill, and gears.

- Inspect belts and pulleys for signs of wear or damage.

- Ensure the table and base are level and secure.

Regular lubrication and inspection keep the drill press running smoothly and efficiently.

Credit: www.homedepot.com

Frequently Asked Questions

What Does Drill Press Swing Mean?

Drill press swing is the distance between the spindle center and the column, doubled. It determines the maximum width of material that can be drilled.

How Do You Measure Drill Press Swing?

To measure drill press swing, measure the distance from the spindle center to the column. Then, double this measurement.

Why Is Drill Press Swing Important?

Drill press swing is important because it determines the maximum width of material that can be drilled. It influences the versatility of the drill press.

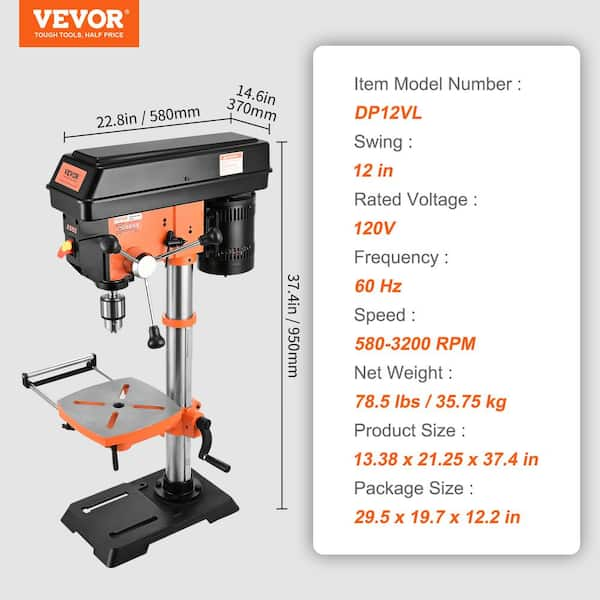

What Is A Good Drill Press Swing Size?

A good drill press swing size depends on your projects. For general use, a 12-inch swing is versatile and common.

Conclusion

Understanding drill press swing is crucial for accurate drilling projects. It determines the machine’s capacity and reach. Always consider swing size before purchasing. This ensures compatibility with your needs. A larger swing offers more flexibility. Smaller swings suit precise, detailed work.

Choose wisely based on your tasks. Proper knowledge leads to better results. Remember, a suitable drill press enhances efficiency and precision. Equip yourself with this knowledge for informed decisions. Happy drilling!