You can drill an asphalt driveway using a masonry or carbide-tipped drill bit. Use steady pressure, keep the bit cool with water, and work slowly to avoid cracks or damage.

Drilling into an asphalt driveway can feel intimidating if you’ve never done it before. Whether you’re installing a fence post, anchoring a basketball hoop, or running cables, knowing the right drill bit and technique makes all the difference. The good news is you don’t need expensive equipment or advanced skills—just the right tools and a few simple safety steps. In this guide, you’ll learn exactly which drill bit works best for asphalt, how to drill without causing cracks, and key tips to finish the job safely and smoothly. Let’s walk through it together, step by step!

Article Summary

- Can You Drill Into an Asphalt Driveway?

- What Drill Bit Can Drill an Asphalt Driveway?

- Tools and Materials You’ll Need

- Step-by-Step Guide to Drilling an Asphalt Driveway

- Common Mistakes to Avoid

- Alternatives to Drilling Asphalt

- Safety Tips for Drilling an Asphalt Driveway

- Maintenance Tips After Drilling

- Conclusion

Can You Drill Into an Asphalt Driveway?

Yes, you absolutely can drill into an asphalt driveway if you use the right tools and know what to expect. Over my years working on both small residential driveways and large parking areas, I’ve found that people often worry the asphalt will crack or crumble. The truth is, asphalt is flexible but delicate — it can be drilled if you apply steady pressure and use proper cooling.

People usually need to drill asphalt for things like installing signposts, fencing, or running cables for lighting. Sometimes homeowners even drill to anchor a basketball hoop or mailbox. It’s always smart to check your local codes and call utility services before you drill. For U.S. readers, I recommend using Call 811 to avoid hitting underground lines.

What Drill Bit Can Drill an Asphalt Driveway?

Over the years, I’ve tested various bits on asphalt and similar surfaces. I strongly suggest using masonry drill bits or carbide-tipped bits. These are tough enough to cut through compacted asphalt and small stones in the mix.

If you need to drill a larger hole (over 2 inches), an asphalt core drill bit is best. This is the same type professionals use for paving jobs. It cuts a clean, round plug out of the asphalt with less cracking than a regular twist bit.

When comparing bits, always pick one designed for concrete or masonry, not wood or metal. Asphalt is softer than concrete but still needs a hard, heat-resistant cutting edge. I trust brands like Bosch, DeWalt, or Hilti for reliable masonry bits.

For more advice on choosing drill bits for tough surfaces, check out this guide by Bob Vila.

Tools and Materials You’ll Need

Before I grab my drill, I always make sure I have everything ready. Here’s what I recommend:

| Item | Purpose |

| Hammer drill or rotary drill | Delivers the right power for masonry work |

| Masonry or carbide-tipped bit | Cuts through asphalt effectively |

| Protective gloves and safety glasses | Protects hands and eyes from flying debris |

| Dust mask or respirator | Prevents inhaling fine dust |

| Spray bottle of water | Keeps the drill bit cool and reduces dust |

| Chalk or marker | Marks the exact spot to drill |

| Vacuum or broom | Cleans up loose debris afterwards |

When I’m working on a hot day, I always keep extra water handy to cool the drill bit. This extends the bit’s life and keeps the hole clean. It also helps prevent the bit from binding or getting stuck in sticky asphalt.

Now that you know what you need, I’ll show you how to drill step by step in the next part.

Step-by-Step Guide to Drilling an Asphalt Driveway

Over the last fifteen years, I’ve drilled holes in all kinds of asphalt—old driveways, fresh paving, and even busy parking lots. Follow these simple steps to get a clean hole every time without tearing up the surface.

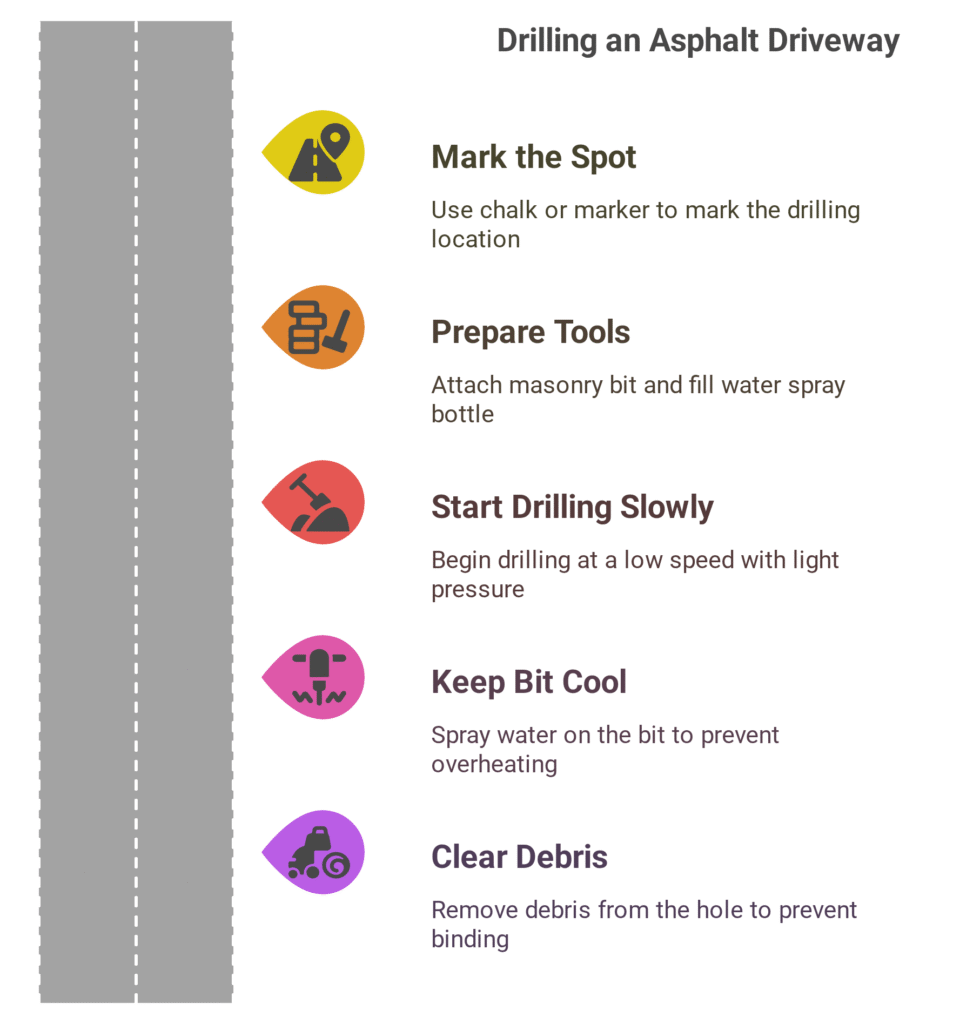

1. Mark the Spot

Use a chalk line or marker to clearly mark where you want to drill. Double-check your measurements. I always remind folks to look at any underground utility maps before drilling. In the U.S., you can check by calling 811.

2. Prepare Your Tools

Make sure your drill has a masonry bit attached and check that your water spray bottle is full. Wear gloves, safety glasses, and a dust mask. I never skip this step—bits can break, and asphalt dust is nasty to breathe in.

3. Start Drilling Slowly

Place the drill bit on your mark and start at a low speed. Apply steady, light pressure. Let the bit cut; don’t force it. If you push too hard, the asphalt may crack or chip.

4. Keep the Bit Cool

While drilling, spray water on the bit every few seconds. This keeps it from overheating and helps carry away debris. When I skip this, I end up burning through bits too fast.

5. Clear Debris and Check Depth

Pull the drill back out every few inches to clear loose bits and check your progress. This stops the bit from binding and keeps the hole clean.

When you’re done, vacuum or sweep up the area. For deeper or wider holes, consider renting an asphalt core drill from a local hardware store. Many stores like Home Depot rent these for a day rate.

Common Mistakes to Avoid

I’ve seen many people ruin a good driveway by rushing. Here are the big mistakes I always warn about:

Using the Wrong Bit

Don’t use a wood or metal bit—they dull fast and can damage your drill. Stick with masonry or carbide-tipped bits for asphalt.

Applying Too Much Force

Pushing hard does more harm than good. Gentle, steady pressure protects the surface and your bit.

Skipping Water Cooling

If you drill dry, you’ll overheat the bit and scorch the asphalt. Always keep a spray bottle handy.

Ignoring Utility Lines

Before drilling deep holes, call a local service to mark buried cables or pipes. This step costs nothing but saves you from a disaster. For more, see OSHA’s guidelines on excavation safety.

Alternatives to Drilling Asphalt

Sometimes I tell DIYers to consider other options if drilling seems risky or if the project is too big.

Use a Core Drill Service

For wide holes, hiring a pro with a core drill saves time and makes perfect cuts. It’s worth the cost for projects like signposts or big pipes.

Cut and Patch

If you only need a trench or square cut, using a cut-off saw might work better than drilling. Afterward, patch the area with cold patch asphalt. I like the QUIKRETE Cold Patch for small repairs.

Hire a Contractor

When in doubt, call a paving contractor. They have the right gear and experience for big jobs and can handle repairs if needed.

Next, I’ll break down safety tips so you can drill without accidents or extra costs.

Safety Tips for Drilling an Asphalt Driveway

Safety is always my top priority when I work with drills and heavy-duty bits. Even though asphalt seems easy to drill, skipping basic safety steps can cause big trouble.

Wear Proper Gear

I always wear safety glasses, gloves, and a dust mask. Flying debris can hurt your eyes or skin. Asphalt dust isn’t healthy to breathe in, so I cover my nose and mouth.

Check the Weather

Try to drill on a cool, dry day. Heat can soften asphalt, making it sticky. Rain makes the surface slippery and messy. If I must drill in warm weather, I use extra water to keep the drill bit cool.

Stay Aware of Surroundings

Before I start, I check for cars, kids, and pets. I also tell anyone nearby to keep back. When using electric drills, I make sure the cord won’t get wet. For more on safe power tool use, I suggest reading OSHA’s Hand and Power Tool Safety.

Know When to Stop

If the bit jams or makes loud grinding noises, I stop right away. I pull the bit out, clear debris, and check for damage. Forcing a stuck bit can break your drill or ruin the asphalt.

Maintenance Tips After Drilling

When I finish drilling, I take a few extra minutes to keep my tools and driveway in good shape. This helps avoid future problems and costly repairs.

Clean the Hole

I vacuum out all the dust and bits. This is important if I’m adding an anchor or bolt. A clean hole holds better and stops water from getting under the surface.

Seal the Edges

If the hole edges look rough, I patch them with cold patch asphalt. This keeps water out and prevents cracks from spreading. Small repairs like this are quick but save money later. For good patch products, I trust brands like Sakrete and QUIKRETE.

Check Your Tools

After each project, I clean my drill bits and check for wear. A dull bit works slower and heats up more, which can damage your drill motor. I store my bits in a dry box to stop rust.

Conclusion

Drilling an asphalt driveway might look tricky, but with the right drill bit, a steady hand, and a few smart steps, anyone can do it safely. I’ve drilled countless holes for fence posts, gates, and even flagpoles—always with simple tools you can find at your local store.

By following this guide, you’ll avoid common mistakes, protect your driveway, and keep your tools in top shape. If you ever feel unsure, don’t hesitate to reach out to a local contractor or visit trusted sources like Family Handyman for more DIY tips.

Got your tools ready? Take your time, stay safe, and you’ll get a neat, clean hole every time. Happy drilling!