Drilling straight without a drill press can seem challenging. But it’s possible with the right techniques.

Whether you’re a DIY enthusiast or tackling a small project, drilling straight holes is often necessary. Without a drill press, this task may seem daunting. But don’t worry. There are simple methods to ensure precision. You don’t need fancy equipment or advanced skills.

Just a few tips and tricks can make a big difference. This guide will walk you through practical steps to drill straight. You’ll find it easier than you think. With a steady hand and some patience, you can achieve professional results. Let’s dive into the details and make drilling straight a breeze.

Article Summary

Tools Needed

Drilling straight without a drill press might seem tricky. But with the right tools, it’s entirely doable. Let’s dive into the essential tools you need to get the job done efficiently.

Basic Hand Drill

A basic hand drill is your primary tool. It’s versatile and easy to use. Choose a drill that fits comfortably in your hand. A good grip helps you control the drill better.

Ensure it has variable speed settings. This allows you to adjust the drilling speed based on the material. Slower speeds are best for metal, while faster speeds work well for wood.

Essential Accessories

Having the right accessories is crucial for drilling straight holes. Let’s look at some must-have items:

- Drill Bits: Use the appropriate drill bit for the material. Wood, metal, and masonry all require different bits.

- Drill Guide: A drill guide helps keep your drill at the correct angle. It ensures your holes are straight.

- Clamps: Clamping your workpiece keeps it steady. This reduces movement and ensures accuracy.

- Center Punch: Mark the spot where you want to drill. A center punch creates a small dent, preventing the drill bit from wandering.

- Level: A small bubble level can be attached to your drill. It helps maintain a straight line.

These tools and accessories will help you drill straight holes. They ensure precision and accuracy, even without a drill press.

Choosing The Right Drill Bit

Drilling straight without a drill press can be challenging. But, using the right drill bit can make a big difference. This section will guide you in choosing the best drill bit for your needs.

Types Of Drill Bits

Different drill bits serve different purposes. Here are some common types:

- Twist Drill Bits: These are the most common. They work well for wood, metal, and plastic.

- Spade Bits: Ideal for drilling larger holes in wood.

- Brad Point Bits: Perfect for precise wood drilling.

- Masonry Bits: Best for drilling into brick, stone, or concrete.

- Forstner Bits: Used for creating clean, flat-bottomed holes in wood.

Selecting The Correct Size

Choosing the right size drill bit is crucial. The wrong size can cause issues. Here are some tips:

- Check your project requirements. Use the size recommended.

- For screws, match the bit size to the screw’s shaft. Not the threads.

- If drilling a pilot hole, choose a bit slightly smaller than the screw.

- Measure the diameter of the bit with a caliper for precision.

| Material | Recommended Drill Bit | Common Sizes |

|---|---|---|

| Wood | Twist, Spade, Brad Point | 1/16″ to 1″ |

| Metal | Twist | 1/16″ to 1/2″ |

| Masonry | Masonry | 1/8″ to 1/2″ |

By choosing the right drill bit, you can achieve a straighter hole. This simple step can lead to better results in your drilling projects.

Preparing The Work Surface

Preparing your work surface is crucial for drilling straight without a drill press. A stable and well-prepared surface ensures precision and safety. Follow these steps to get your workspace ready.

Securing The Material

First, make sure your material is secure. Use clamps to hold it in place. This prevents movement and ensures a straight drill. Here’s how you can do it:

- Place your material on a flat, sturdy surface.

- Position clamps at each corner of the material.

- Tighten the clamps until the material is firmly held.

A well-secured material reduces errors and keeps your hands safe.

Marking The Drilling Point

Next, mark the exact point where you want to drill. Clear markings guide your drill bit, ensuring it stays straight. Here’s a simple method:

- Use a ruler to measure the spot accurately.

- Mark the point with a pencil or marker.

- Double-check the position to ensure accuracy.

For better precision, create a small dent at the marked spot with a center punch. This helps the drill bit stay in place.

By securing the material and marking the drilling point, you lay the foundation for accurate and straight drilling. These steps are simple but essential for success.

Credit: www.youtube.com

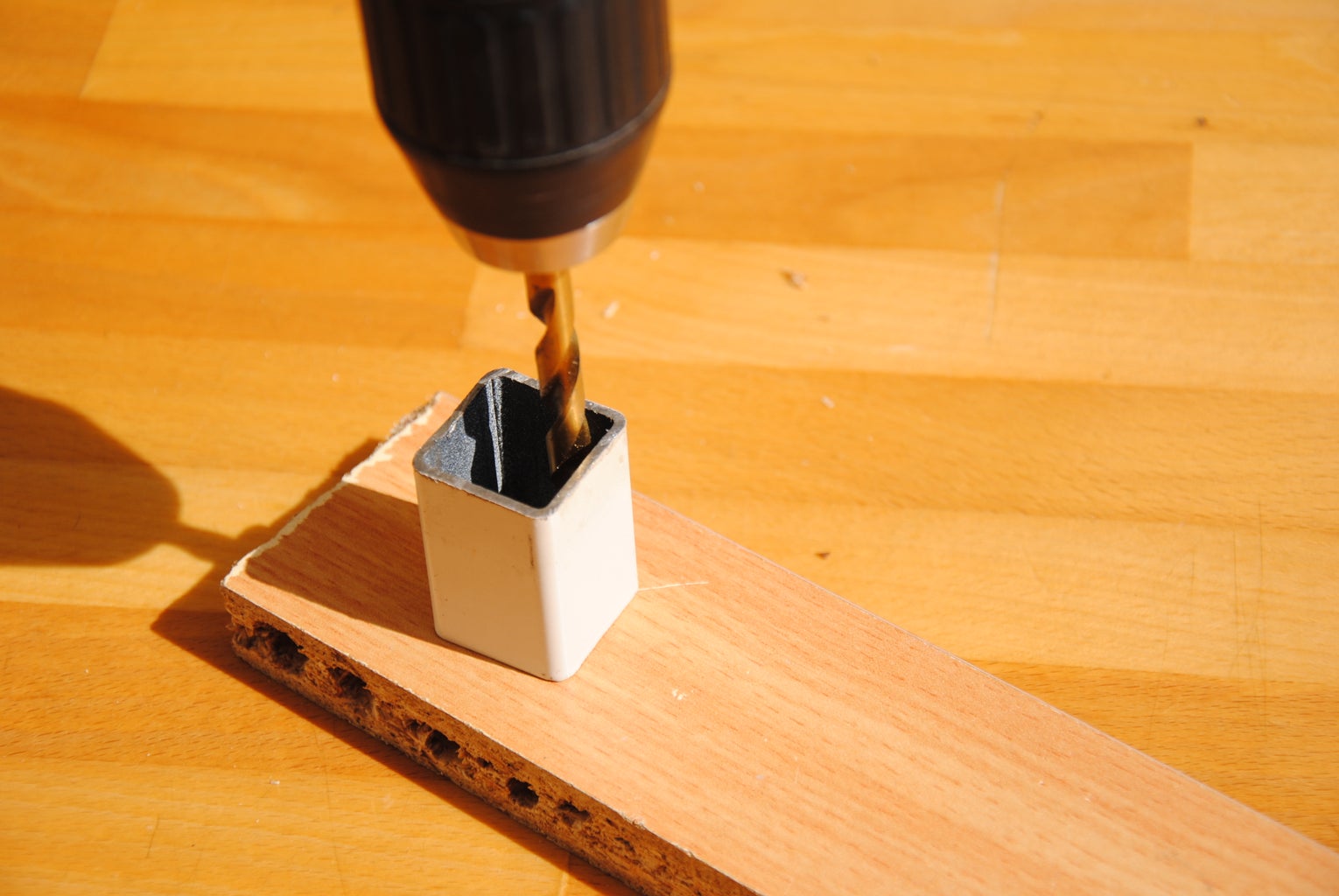

Using A Drill Guide

Drilling straight holes without a drill press can be challenging. A drill guide can help you achieve straight, accurate holes. This tool is designed to guide your drill bit, making your work easier and more precise.

Benefits Of A Drill Guide

A drill guide offers many advantages. It helps you drill straight holes consistently. This is crucial for projects where precision is key. It also reduces the risk of damaging your workpiece. The guide stabilizes your drill, which minimizes wobbling. This results in cleaner, more accurate holes.

Using a drill guide saves time. You won’t need to redo holes or fix mistakes. It also makes your work look more professional. A neat, straight hole is always better than a crooked one. Plus, it’s safer. The guide keeps the drill steady, reducing the risk of slips and accidents.

How To Set Up

Setting up a drill guide is simple. First, choose the right drill bit for your project. Attach the drill bit to your drill. Next, position the drill guide on your workpiece. Make sure it’s aligned with the spot where you want to drill. Secure the guide in place. Some guides come with clamps to help with this step.

Adjust the depth stop if your guide has one. This ensures you don’t drill too deep. Turn on your drill and start drilling. Keep the drill steady and let the guide do its job. Once you’re done, remove the guide and inspect your work. You should have a straight, clean hole.

Creating A Starter Hole

Creating a starter hole is a key step to drill straight without a drill press. It ensures your drill bit stays on target and doesn’t wander off. This simple step can make a big difference in the accuracy of your drilling.

Why It’s Important

A starter hole acts as a guide for your drill bit. It helps you begin drilling at the right spot. Without a starter hole, your drill bit may slip. This could lead to mistakes and uneven holes. A starter hole also makes drilling easier and faster. The drill bit will cut more smoothly, giving you better control.

Step-by-step Process

First, mark the spot where you want to drill. Use a pencil or a marker for this. Next, take a nail or an awl. Place it on the marked spot. Tap it gently with a hammer. This will create a small dent in the surface. This is your starter hole.

Check the dent to make sure it’s deep enough. It should be visible but not too deep. If it’s not deep enough, tap it again. The starter hole is now ready. You can start drilling with confidence. The drill bit will stay in place and follow the guide.

Use this method every time you need to drill a straight hole. It’s a simple yet effective technique. Practice it a few times to get the hang of it. Soon, drilling straight holes will become second nature to you.

Credit: www.instructables.com

Maintaining Drill Alignment

Drilling straight holes without a drill press can be tricky. But it is possible. You need to maintain the drill alignment. This ensures precision and avoids mistakes. Here’s how you can do it effectively.

Visual Techniques

One way to maintain drill alignment is by using visual techniques. These methods rely on your sight to keep the drill straight.

- Mark a Straight Line: Draw a straight line on the material. Follow this line while drilling.

- Use a Guide: Create a simple guide with scrap wood. Hold it next to the drill bit.

- Check from Different Angles: Look from above and the sides. Ensure the drill stays aligned.

Using A Square

A square can help maintain drill alignment. This tool ensures your drill stays at a right angle.

- Position the Square: Place the square on the material. Align it with the drill bit.

- Check the Angle: Look at the angle from different sides. Adjust the drill if needed.

- Drill Slowly: Start drilling slowly. Keep checking the alignment as you go.

Using a square might take practice. But it ensures accuracy. This simple tool can help achieve straight holes.

| Method | Tools Needed | Difficulty Level |

|---|---|---|

| Visual Techniques | None or simple guides | Medium |

| Using a Square | Square tool | Easy |

Maintaining drill alignment is crucial. Whether using visual techniques or a square, practice is key. These methods will help you drill straight without a drill press.

Alternative Methods

Drilling straight without a drill press can be challenging. Fortunately, there are several alternative methods to achieve precise results. Below are some effective techniques to consider.

Homemade Jigs

A homemade jig can help you drill straight. Create a simple jig using scrap wood. Follow these steps:

- Cut two pieces of wood at 90-degree angles.

- Attach them together to form an L-shape.

- Clamp the L-shaped jig to your workpiece.

- Use the vertical piece to guide your drill.

This method ensures your drill bit remains straight. You can also adjust the jig for different angles.

Angle Blocks And Clamps

Angle blocks and clamps are another great option. Here’s how to use them:

- Choose an angle block that matches your desired angle.

- Secure the angle block to your workpiece using clamps.

- Place your drill against the angle block.

- Drill through the guide hole in the angle block.

This setup keeps your drill aligned. It’s perfect for repetitive tasks. Angle blocks can be purchased or made from wood.

Safety Tips

Drilling straight without a drill press can be tricky. Safety should always be your top priority. Here are some essential safety tips to keep you safe and ensure accurate drilling.

Wearing Protective Gear

Always wear proper protective gear. This includes safety goggles to protect your eyes from debris. Wear ear protection to safeguard your hearing from loud drilling noises. Don’t forget gloves to protect your hands from cuts and bruises. Ensure you wear a dust mask to prevent inhaling harmful particles.

Avoiding Common Mistakes

Common mistakes can lead to accidents. Here are some tips to avoid them:

- Secure the material: Always clamp the material you are drilling. This prevents it from moving.

- Check the drill bit: Ensure the drill bit is sharp and suitable for the material.

- Use a guide: A guide helps keep the drill straight. Consider using a drilling jig or a block of wood as a guide.

Following these safety tips can make your drilling tasks safer and more efficient.

Credit: www.instructables.com

Frequently Asked Questions

What Tools Can Help Drill Straight?

Using a drill guide, spirit level, or a right-angle jig can ensure straight drilling. These tools help maintain accuracy and precision, even without a drill press.

How To Stabilize The Drill?

To stabilize the drill, use a clamp to secure the workpiece. Keep a firm grip and apply steady pressure while drilling.

Can A Handheld Drill Achieve Straight Holes?

Yes, a handheld drill can achieve straight holes. Using guides, clamps, and maintaining steady hand control can ensure straight drilling.

What Is A Drill Guide?

A drill guide is a tool that assists in keeping the drill bit aligned. It ensures the hole is drilled straight and accurately.

Conclusion

Drilling straight without a drill press is possible. Use simple tools and techniques. Practice steady hand control. Ensure your work surface is stable. Use guides like a square or level. A well-marked starting point helps. Patience and precision go a long way.

With these tips, you can achieve straight holes. No need for complex equipment. Your projects will turn out well. Happy drilling!