Choosing the right drill bit for an anchor can be tricky. The wrong bit can ruin your project.

Drill bits come in many types and sizes. Understanding the differences is key. An anchor needs a precise hole to work effectively. This guide will help you pick the perfect drill bit for your anchor. We will explore different types of drill bits, materials, and sizes.

With the right information, you can avoid common mistakes. Ready to make your project a success? Let’s dive into the details.

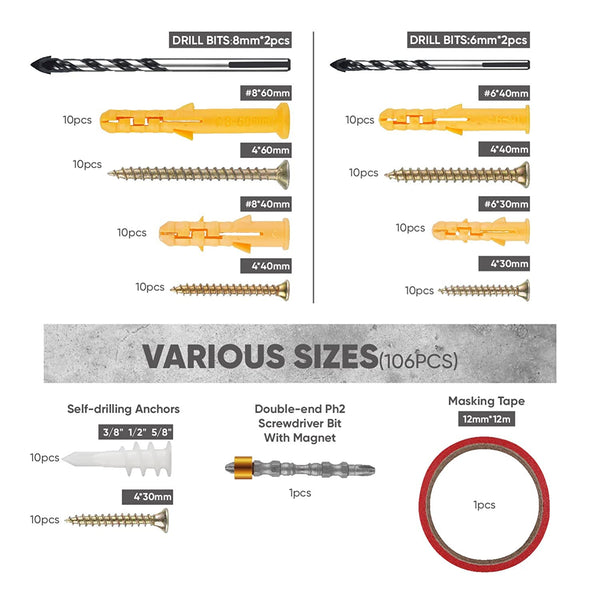

Credit: toolant.com

Article Summary

Types Of Drill Bits

When it comes to choosing the right drill bit for an anchor, it can feel like navigating a maze. But don’t worry! Let’s break it down into simple parts. There are different types of drill bits depending on the material you’re working with. In this section, we’ll explore the main types: masonry bits, wood bits, and metal bits.

Masonry Bits

Masonry bits are your go-to when working with hard materials like brick, concrete, or stone. These bits are usually tipped with carbide, making them super tough and durable. Picture this: you’re trying to hang a picture on a brick wall. Using a masonry bit, you can drill a hole for the anchor with ease.

Key Features:

- Carbide tip for durability

- Designed for hard surfaces

- Available in various sizes

Remember, when using masonry bits, keep the drill speed low to avoid overheating. Slow and steady wins the race!

Wood Bits

Wood bits, also known as spade bits, are perfect for drilling into wood. They often have a pointed tip to help you start the hole exactly where you want it. Imagine you’re building a new bookshelf. A wood bit will make neat holes for your screws and anchors.

Key Features:

- Pointed tip for precision

- Flat, paddle-like shape

- Ideal for various types of wood

Pro tip: Keep your wood bits sharp. A dull bit can make your work harder and the holes less clean.

Metal Bits

Metal bits are designed to cut through tough materials like steel or aluminum. These bits are usually made from high-speed steel (HSS) and have a different shape compared to wood or masonry bits. For example, if you’re installing a metal bracket, a metal bit will drill the necessary holes without breaking a sweat.

Key Features:

- Made from high-speed steel

- Can cut through tough metals

- Often have a twist design

Tip: Use cutting oil to keep the bit cool and extend its life. Metal bits can get really hot!

Choosing the right drill bit for your anchor doesn’t have to be a guessing game. By knowing the types of bits and their uses, you can make your project go smoothly. Whether you’re working with masonry, wood, or metal, there’s a perfect bit out there for you.

Credit: www.youtube.com

Understanding Anchor Types

Choosing the right drill bit for an anchor can be tricky if you don’t understand the types of anchors available. Knowing the different types will help you select the perfect drill bit for your project. Let’s delve into the common types of anchors you’ll encounter: plastic anchors, metal anchors, and toggle bolts. Each type has its unique characteristics and uses, making them suitable for various tasks. By understanding these anchor types, you’ll be better equipped to make informed decisions and ensure your project’s success.

Plastic Anchors

Plastic anchors are often used for light-duty tasks. They are made from durable plastic and expand when a screw is inserted, creating a secure hold in drywall or plaster. They are ideal for hanging lightweight items like pictures or small shelves. When choosing a drill bit for plastic anchors, ensure the bit matches the diameter of the anchor to prevent loose fits or damaging the anchor.

- Advantages: Easy to use, affordable, versatile.

- Disadvantages: Limited load capacity, not suitable for heavy-duty use.

Metal Anchors

Metal anchors are designed for heavy-duty applications. They provide strong support and are perfect for securing items in concrete, brick, or masonry. Metal anchors come in various types such as sleeve anchors and wedge anchors, each suitable for different materials and load requirements. When selecting a drill bit for metal anchors, it’s crucial to match the size and type of anchor to ensure a tight fit and maximum holding power.

- Advantages: High load capacity, durable, reliable.

- Disadvantages: More expensive, require precise installation.

Toggle Bolts

Toggle bolts are fantastic for hollow wall installations. These anchors consist of a bolt and spring-loaded wings that expand behind the wall, offering robust support. They are ideal for hanging heavy objects on drywall or plaster without the need for studs. To use toggle bolts, choose a drill bit that matches the size of the bolt’s body, ensuring the wings can expand properly once inserted.

- Advantages: Excellent for hollow walls, strong holding power.

- Disadvantages: More complex installation, can be challenging to remove.

In conclusion, understanding the different types of anchors helps you choose the right drill bit for your project. Whether you’re hanging a picture or mounting a heavy shelf, knowing the specifics of plastic anchors, metal anchors, and toggle bolts ensures you select the appropriate tools and techniques. Remember, the right anchor paired with the right drill bit makes all the difference in the stability and durability of your installation.

Assessing Material Composition

When it comes to choosing the right drill bit for an anchor, understanding the material composition of what you’re drilling into is paramount. Different materials require different drill bits to ensure a secure and stable anchor. Let’s dive into the specifics of how to assess the material composition for various surfaces.

Concrete And Brick

Concrete and brick are tough and durable materials, but they need special drill bits. You’ll want to use masonry drill bits for these surfaces. These bits are designed to cut through hard materials without getting worn out quickly. They usually have a tungsten carbide tip that makes them extra tough. When drilling into concrete, it’s important to start slow and increase speed gradually to avoid cracking the material. For brick, you might find it easier to use a hammer drill along with your masonry bit to make the job smoother.

Drywall And Plaster

Drywall and plaster are much softer compared to concrete and brick. A standard twist bit works well here. These bits are commonly available and they’re perfect for drilling into softer materials. However, be gentle while drilling because these surfaces can crumble if you’re too aggressive. Also, consider using anchors specifically designed for drywall, as they expand behind the wall to provide better support.

Wood And Metal

Wood and metal have their own unique challenges. For wood, a spade bit or an auger bit would be ideal. These bits make clean holes without splintering the wood. On the other hand, metal requires high-speed steel (HSS) bits. These are designed to withstand the heat and friction generated when drilling into metal. Remember, when drilling into metal, use a lubricant like oil to keep the bit cool and reduce wear.

Choosing the right drill bit for the material you’re working with can make all the difference. Not only does it make your job easier, but it also ensures that your anchors hold firm. So, next time you’re facing a drilling project, take a moment to assess the material composition and select the appropriate drill bit for the task. Your walls (and your sanity) will thank you!

Matching Drill Bit Size To Anchor

Choosing the right drill bit size for an anchor is crucial. The correct size ensures a secure fit and prevents damage to the wall. Let’s explore how to match the drill bit size to the anchor effectively.

Reading Size Charts

Size charts are your best friend in this process. They list the recommended drill bit sizes for different anchors. Always check the manufacturer’s guidelines. These charts are usually on the anchor packaging or the manufacturer’s website.

Compare the anchor size with the chart. Look for a match. If you have a 1/4-inch anchor, the chart will tell you the exact drill bit size needed. Sometimes, you may find the size in millimeters. Convert if necessary.

Using Measurement Tools

Measurement tools like calipers can be very helpful. They measure the anchor’s diameter accurately. Place the caliper around the anchor’s widest part. Note the measurement. This step ensures precision and avoids guesswork.

A tape measure can also work. Wrap it around the anchor’s thickest part. Read the measurement in inches or millimeters. Double-check your reading for accuracy. This ensures that your drill bit size is perfect for the anchor.

Considering Drill Bit Coatings

When you’re choosing a drill bit for an anchor, the coating on the drill bit can make a big difference. Coatings enhance the durability and performance of drill bits, making them more efficient for various tasks. Let’s dive into two popular types of coatings: titanium and cobalt. Each has its own unique benefits, so let’s see which one suits your needs best.

Titanium Coated

Titanium-coated drill bits are a popular choice for many DIY enthusiasts and professionals. These drill bits are coated with a layer of titanium nitride, which makes them incredibly tough and long-lasting. Here’s why you might consider using titanium-coated drill bits:

- Durability: The titanium coating makes the drill bit harder and more resistant to wear.

- Heat Resistance: This coating helps the bit stay cool, even when drilling through tough materials.

- Versatility: Suitable for a variety of materials like wood, plastic, and soft metals.

- Cost-Effective: While they might be pricier than uncoated bits, their longevity means you won’t need to replace them as often.

Personal Anecdote: I remember the first time I used a titanium-coated drill bit. It was like a hot knife through butter – smooth and effortless. I was drilling through a metal sheet, and the bit stayed cool and sharp throughout the task. Quite a game-changer!

Cobalt Coated

Cobalt-coated drill bits are another excellent choice, particularly when dealing with tougher materials. These bits are made from a high-speed steel alloy with cobalt, making them extremely hard and heat resistant. Here’s what makes cobalt-coated drill bits stand out:

- Extreme Hardness: Cobalt adds hardness and strength, making these bits ideal for drilling through very hard materials like stainless steel and cast iron.

- Heat Resistance: They can withstand higher temperatures without losing their edge, perfect for high-speed drilling.

- Longevity: These bits tend to last longer, even under heavy use.

- Precision: Ideal for precise drilling tasks where accuracy is crucial.

Subtle Humor: If a titanium-coated bit is like a hot knife through butter, then a cobalt-coated bit is like a lightsaber through Jell-O. It’s that good!

So, which one should you choose? If you’re drilling through softer materials and looking for a cost-effective option, titanium-coated drill bits are a great choice. However, if you’re dealing with tough, hard materials and need something that can handle the heat, cobalt-coated drill bits are the way to go.

Remember, the right coating can make your drilling tasks easier and more efficient. Choose wisely and happy drilling!

Drill Bit Durability

When it comes to choosing the right drill bit for an anchor, drill bit durability is a key factor. You want a tool that can withstand the test of time and the rigors of your projects. But how do you know if a drill bit is durable? Let’s dive into the details.

Longevity

Longevity refers to how long a drill bit will last before it needs replacing. Imagine you’re working on a big project, and halfway through, your drill bit gives up on you. Frustrating, right? To avoid this, look for drill bits made from high-quality materials like cobalt or carbide. These materials are known for their strength and can drill more holes over time compared to regular steel bits.

Another tip is to check the manufacturer’s warranty. A good warranty often indicates that the company stands behind its product. So, if they say it will last, it probably will.

Resistance To Wear

Resistance to wear is all about how well a drill bit can handle continuous use without losing its edge. If you’ve ever had a drill bit go dull on you, you know how annoying that can be. A dull bit makes work harder, slower, and can even damage your materials.

To ensure resistance to wear, look for drill bits with coatings like titanium or black oxide. These coatings reduce friction and heat buildup, both of which can make a bit wear out faster. A bit with a good coating can last significantly longer, saving you time and money in the long run.

So, when you’re on the hunt for a durable drill bit, remember to consider both longevity and resistance to wear. Your future self will thank you!

Safety Tips

Choosing the right drill bit for an anchor involves more than just selecting the correct size. Safety is a crucial aspect to consider. Using a drill improperly can lead to accidents and injuries. Below are some important safety tips to keep in mind.

Wearing Protective Gear

Always wear safety goggles to protect your eyes from flying debris. Dust and small particles can cause serious eye injuries. Gloves are also essential. They provide a better grip and protect your hands. Consider wearing ear protection. Drills can be noisy and harmful to your ears over time.

Ensuring Proper Handling

Always hold the drill with both hands for better control. This helps in preventing slips and accidents. Make sure the drill bit is tightly secured before starting. A loose bit can wobble and cause injuries. Use the correct speed setting for the material you are drilling. Higher speeds are not always better.

:max_bytes(150000):strip_icc()/how-to-use-and-discard-anchor-screws-1822671_01_3222-d91010bb83f841aa8c626ff057e8f318.jpg)

Credit: www.thespruce.com

Maintenance And Care

Choosing the right drill bit for an anchor is just the beginning. To keep your drill bits in perfect condition and ensure they last a long time, you need to maintain and care for them properly. In this section, we’ll look at how to clean and store your drill bits to keep them in top shape.

Cleaning Drill Bits

Cleaning your drill bits is essential for keeping them sharp and effective. Here’s a simple guide:

- Remove debris: After using a drill bit, brush off any dust or debris. This keeps the bit from becoming dull.

- Wipe with a cloth: Use a clean, dry cloth to wipe the bit. This helps remove any remaining particles.

- Use a lubricant: Occasionally, apply a bit of lubricant or oil. This prevents rust and keeps the bit moving smoothly.

Remember, a clean drill bit is a happy drill bit! It makes your drilling job easier and extends the bit’s life.

Proper Storage

Storing your drill bits properly is just as important as cleaning them. Here are some tips:

- Use a case: Most drill bits come with a storage case. Use it! It keeps them organized and protected.

- Avoid moisture: Store your bits in a dry place. Moisture can cause rust, which dulls the bits.

- Keep them separate: If you don’t have a case, keep each bit separate from others. This prevents them from banging into each other and getting damaged.

Think of your drill bits as tiny soldiers. They need a clean, dry barracks to stay ready for action!

By following these simple steps for cleaning and storing your drill bits, you’ll ensure they remain sharp, effective, and ready for your next project. It’s a small effort that makes a big difference.

Frequently Asked Questions

How Do You Match A Drill Bit To An Anchor?

Choose a drill bit that matches the diameter of the anchor. Check the anchor packaging for the correct size.

Which Drill Bit To Use For Anchors?

Use a drill bit that matches the size of your anchor. Typically, masonry bits are ideal for concrete and brick surfaces. Ensure the hole depth aligns with the anchor length.

How To Figure Out What Drill Bit To Use?

Choose a drill bit based on the material you’re drilling. Match the size to your screw or anchor. Check manufacturer guidelines.

What Size Hole Do You Drill For Anchor Bolts?

Drill a hole matching the anchor bolt diameter. For example, use a 1/2-inch drill bit for a 1/2-inch anchor bolt. Always check the manufacturer’s instructions for precise requirements.

Conclusion

Choosing the right drill bit for an anchor is essential. It ensures a strong, secure hold. Understand your material and anchor type. Measure the correct hole size. Always use quality tools. This prevents unnecessary wear and tear. Test a small spot first.

It helps avoid mistakes. Follow these steps for safe, effective drilling. Your projects will last longer. Enjoy the confidence of a job well done. Happy drilling!