Choosing between a brushless drill and a brushed drill can be confusing. Both have their own strengths and weaknesses.

Understanding the differences between these two types of drills is crucial for any DIY enthusiast or professional. The choice impacts performance, durability, and cost. Brushless drills are known for their efficiency and longer lifespan. Brushed drills, on the other hand, are often more affordable and simpler to maintain.

This comparison aims to clarify these key distinctions. By the end, you will know which drill suits your needs best. Whether you prioritize power or budget, this guide will help you make an informed decision. Let’s dive into the world of drills and find out which one is right for you.

Article Summary

Introduction To Brushless And Brushed Drills

Choosing the right drill can be confusing with so many options. Two popular types are brushless drills and brushed drills. Understanding their differences can help you make the right choice for your projects. Both have unique features, advantages, and disadvantages. Let’s dive into the details.

What Is A Brushless Drill?

A brushless drill uses modern technology to improve performance. It has an electronic circuit board and a sensor. The sensor sends signals to the circuit board, which then powers the motor. This design eliminates the need for brushes.

Brushless drills are more efficient and have a longer lifespan. They generate less heat and offer more power. These drills are often lighter and quieter. They also adjust their power based on the task, which saves battery life.

Here are some key benefits of brushless drills:

- Higher efficiency

- Longer lifespan

- Less maintenance

- Reduced heat and noise

- Better battery life

What Is A Brushed Drill?

A brushed drill uses older technology with carbon brushes. The brushes transfer electrical current to the motor, causing it to spin. This design has been in use for decades and is still effective.

Brushed drills are often more affordable than brushless drills. They are also easier to repair. However, they do generate more heat and require more maintenance. The brushes wear out over time and need replacement.

Here are some key points about brushed drills:

- More affordable

- Easier to repair

- More maintenance required

- Generates more heat

- Shorter lifespan

Mechanics And Technology

Understanding the mechanics and technology behind drills can help you choose the right one. Brushless and brushed drills differ significantly in their inner workings. This section explains how each type operates.

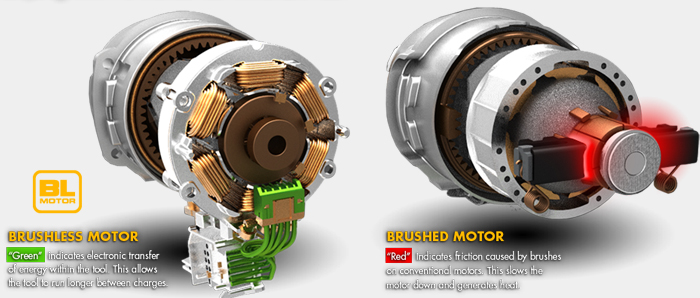

How Brushless Motors Work

Brushless motors use an electronic controller instead of brushes. This controller sends signals to the motor windings. The windings then create a magnetic field. This field interacts with magnets on the rotor. The rotor spins, driving the drill.

Brushless motors are more efficient. They produce less heat and require less maintenance. They also offer more torque and longer battery life. This makes them ideal for heavy-duty tasks.

How Brushed Motors Work

Brushed motors use brushes to conduct electricity. These brushes make contact with a commutator. The commutator is attached to the rotor. As electricity flows, the rotor spins.

Brushed motors are simpler and cheaper. They are easier to repair. But they wear out faster. Brushes generate heat and friction. This reduces efficiency and battery life.

| Feature | Brushless Drill | Brushed Drill |

|---|---|---|

| Efficiency | High | Moderate |

| Maintenance | Low | High |

| Torque | High | Moderate |

| Battery Life | Longer | Shorter |

| Cost | Higher | Lower |

Knowing these differences can help you make an informed decision. Choose the drill that best suits your needs and budget.

Performance Comparison

Choosing between a brushless drill and a brushed drill can be tough. This section will help you understand the performance differences. We will compare power and efficiency, as well as speed and torque.

Power And Efficiency

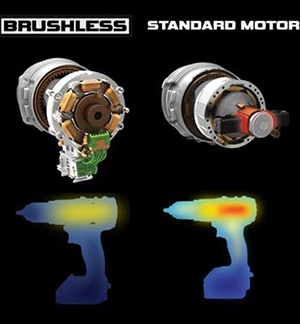

Brushless drills are known for their power and efficiency. They use electronic controllers to deliver power. This makes them more efficient. They also generate less heat.

Brushed drills have mechanical brushes. These brushes cause more friction. This means they are less efficient. They also generate more heat. This can affect performance over time.

| Feature | Brushless Drill | Brushed Drill |

|---|---|---|

| Power | Higher | Lower |

| Efficiency | More Efficient | Less Efficient |

| Heat Generation | Less Heat | More Heat |

Speed And Torque

Speed and torque are key factors in choosing a drill. Brushless drills offer higher speeds and better torque control. They adjust power based on the task. This provides better performance.

Brushed drills have fixed speeds. Their torque control is less precise. They may not perform as well in tougher tasks.

- Brushless Drill

- Higher Speeds

- Better Torque Control

- Brushed Drill

- Fixed Speeds

- Less Precise Torque

Durability And Maintenance

Choosing the right drill can save you time and money. Durability and maintenance are key factors in this decision. Brushless and brushed drills differ in these aspects. Each type has its own advantages and challenges. Let’s explore their lifespans and maintenance needs.

Lifespan Of Brushless Drills

Brushless drills generally have a longer lifespan. They don’t have brushes that wear out over time. The motor runs cooler and cleaner. This reduces the risk of overheating and damage. Less friction means fewer parts to wear down.

Brushless drills often come with advanced electronics. These electronics can adjust power and speed. This precision helps prolong the drill’s life. Regular maintenance is still needed. But, overall, brushless drills require fewer repairs.

Lifespan Of Brushed Drills

Brushed drills have a shorter lifespan. The brushes wear out as they make contact with the motor. This wear and tear can lead to more frequent repairs. Over time, the motor may overheat. This can cause damage and reduce the drill’s efficiency.

Brushed drills need more maintenance. Regularly replacing brushes is necessary. Cleaning the motor is also important. These tasks can extend the drill’s life. But, expect more upkeep compared to brushless models.

Cost And Value

When deciding between a brushless drill and a brushed drill, understanding the cost and value is crucial. This section will break down the initial investment and long-term value, helping you make an informed decision.

Initial Investment

The initial investment for a brushless drill is usually higher. The advanced technology in these drills results in a higher price tag. On the other hand, brushed drills are more budget-friendly. They are often the go-to choice for those with a tight budget.

Here is a simple comparison:

| Type | Average Price |

|---|---|

| Brushless Drill | $100 – $300 |

| Brushed Drill | $50 – $150 |

As shown, the price difference is significant. This is something to consider when making your purchase.

Long-term Value

While the initial cost of a brushless drill is higher, the long-term value can be better. Brushless drills tend to last longer and require less maintenance. They have fewer parts that wear out over time.

Benefits of a brushless drill:

- Longer lifespan

- Less maintenance

- Higher efficiency

In contrast, brushed drills might need more frequent repairs. They also consume more energy, which can add up over time.

Consider this comparison:

| Feature | Brushless Drill | Brushed Drill |

|---|---|---|

| Maintenance | Low | High |

| Energy Efficiency | High | Low |

| Lifespan | 10+ years | 5-7 years |

In the long run, the brushless drill can save you money. This makes it a valuable investment for serious users.

Credit: www.youtube.com

Suitability For Different Tasks

When choosing between a brushless drill and a brushed drill, understanding their suitability for different tasks is essential. Each type has its strengths and is better suited for specific applications. Let’s explore their suitability for various tasks under the following categories.

Diy Projects

Brushless drills are ideal for DIY enthusiasts. They offer longer battery life, which means more time working on your projects. Their efficiency ensures you get more power and precision. This makes them perfect for intricate tasks.

Brushed drills are also good for DIY projects. They are often more affordable and easier to repair. This makes them a practical choice for occasional use. They handle basic tasks like drilling holes or assembling furniture well.

Professional Use

Professionals often prefer brushless drills. These drills are more durable and can handle heavy-duty tasks. They provide more power and less maintenance. This makes them reliable for demanding jobs.

Brushed drills can be used professionally too. They are less expensive and can be a good backup tool. However, they might not last as long with continuous use. Their performance is suitable for less intensive work.

User Experience

The user experience is a critical factor when deciding between a brushless drill and a brushed drill. This section will help you understand how each type affects ease of use and noise levels during operation.

Ease Of Use

Choosing the right drill can make a huge difference in your project. A brushless drill is generally lighter and more compact. This makes it easier to handle, especially in tight spaces. The absence of brushes reduces friction, leading to a smoother operation.

On the other hand, a brushed drill may feel bulkier and heavier. It has a simpler design which can make it easier to repair. However, its higher friction can lead to more wear and tear over time. Let’s look at a quick comparison:

| Feature | Brushless Drill | Brushed Drill |

|---|---|---|

| Weight | Light | Heavy |

| Size | Compact | Bulky |

| Operation | Smooth | Rough |

Noise Levels

Noise is a significant factor in the user experience. A brushless drill operates more quietly due to the lack of brushes. This makes it ideal for indoor projects and reduces noise pollution.

In contrast, a brushed drill tends to be noisier. The friction between the brushes and the commutator creates more sound. This can be distracting and uncomfortable during prolonged use.

Here’s a quick summary:

- Brushless Drill: Quieter operation, less noise pollution.

- Brushed Drill: Noisier, more friction-induced sound.

Understanding these differences can help you make an informed decision and improve your overall user experience.

Credit: ibtinc.com

Environmental Impact

When choosing between a brushless drill and a brushed drill, understanding their environmental impact is crucial. Both types have different effects on energy consumption and carbon emissions. Let’s explore how each type fares in terms of environmental sustainability.

Energy Efficiency

Brushless drills are generally more energy efficient than brushed drills. They use less power to deliver the same performance. This means they consume fewer resources. Less energy consumption translates to lower electricity bills. For those who use drills frequently, this is significant. Brushless drills also produce less heat. This leads to better battery life and reduced wear and tear. Less frequent replacements mean fewer resources are used over time.

Carbon Footprint

Brushless drills tend to have a smaller carbon footprint. They require fewer resources for maintenance and replacement. The manufacturing process of brushless motors is also more efficient. This results in lower emissions during production. Brushed drills, on the other hand, often need more frequent repairs. This leads to higher carbon emissions over their lifespan. Choosing a brushless drill can help reduce your carbon footprint. It is a greener choice for those concerned about the environment.

Credit: www.mtah.net

Frequently Asked Questions

What Is A Brushless Drill?

A brushless drill uses an electronically commutated motor. It provides more efficiency and longevity compared to brushed drills. They are quieter and require less maintenance.

How Does A Brushed Drill Work?

A brushed drill operates with carbon brushes. These brushes transfer current to the motor. It is generally less efficient and louder than brushless models.

Which Drill Is More Efficient?

Brushless drills are more efficient. They use less energy, provide more power, and have a longer lifespan compared to brushed drills.

Are Brushless Drills Worth The Extra Cost?

Yes, brushless drills are worth the extra cost. They offer greater efficiency, longer motor life, and less maintenance. This makes them a valuable investment.

Conclusion

Choosing between a brushless and a brushed drill depends on your needs. Brushless drills offer more efficiency and longer life. They are great for heavy-duty tasks. Brushed drills, on the other hand, are more affordable. They work well for simple, everyday jobs.

Both have their pros and cons. Consider your budget and project requirements. This will help you make the best choice. Happy drilling!