Looking to master precision without the mess? This is a guide to hand drilling in carbon fiber composites that actually works—clean, safe, and beginner-friendly.

I’ll be honest—when I first tried drilling into carbon fiber, I felt like I was defusing a bomb. One wrong move and poof, hundreds of dollars and hours of work could go to waste. But over time, and after some mistakes (okay, many mistakes), I figured out how to do it right.

In this guide, I’ll walk you through everything I’ve learned—step-by-step—so you don’t have to go through the same trial-and-error process. Whether you’re modifying a drone frame, a bike component, or a racing part, this guide will help you hand drill carbon fiber like a pro, safely and accurately.

Article Summary

- What Is Carbon Fiber Composite?

- Why Hand Drilling Instead of Power Drilling?

- Tools You’ll Need

- Step-by-Step: How I Hand Drill Carbon Fiber Composites

- What Can Go Wrong—and How I Fix It

- My Top 10 Tips for Clean Holes Every Time

- Drill Bit Comparison Table

- Safety Tips You Shouldn’t Ignore

- Real-Life Story: My First Disaster and What I Learned

- FAQs On A Guide To Hand Drilling In Carbon Fiber Composites

- Final Thoughts

What Is Carbon Fiber Composite?

Before we even touch a drill, let’s understand what we’re dealing with.

Carbon fiber composites are made of woven carbon fibers bonded together with resin. They’re lightweight, super strong, and incredibly stiff. But here’s the catch—they’re also brittle and layered, which means drilling without care can cause:

- Delamination (layers separating)

- Fraying at the edges

- Cracks that ruin the structural integrity

I learned early on that using the wrong technique or tool turns this high-tech material into a disaster waiting to happen.

Why Hand Drilling Instead of Power Drilling?

Great question—and I get this a lot. Why go “old school” with hand drilling?

Here’s why I stick to hand drilling for carbon fiber:

- Control: I can apply gentle pressure and adjust as needed.

- Reduced Heat: Power drills generate heat that can melt the resin or cause delamination.

- Precision: When working on small parts, like RC arms or bike components, I don’t want to risk over-drilling.

- No Splintering: A steady, manual approach reduces frayed edges.

Tools You’ll Need

Let me make this clear—don’t grab just any drill bit from your toolbox. Using the wrong bit on carbon fiber is like using a steak knife to carve ice.

Here’s what you actually need:

🛠️ Essential Tools

| Tool | Why You Need It |

|---|---|

| Hand drill (manual) | Offers control and prevents overheating |

| Carbide drill bits | Sharp and strong; resist wear |

| Masking tape | Prevents chipping at the surface |

| Clamps | Keeps your workpiece stable |

| Protective gear | Dust mask, gloves, and goggles—trust me, carbon fiber dust is nasty |

| Drilling block | Backing surface to prevent blowouts |

Pro Tip: I always use a brad point or diamond-coated bit for best results.

Step-by-Step: How I Hand Drill Carbon Fiber Composites

Here’s where the magic happens. I’ll break it down into simple steps—just follow along.

🔹 Step 1: Mark Your Spot

First, I place masking tape where I want to drill. This gives the bit something to grip and helps prevent surface fraying. Then I use a fine marker or scribe to mark the exact center of the hole.

🔹 Step 2: Secure Your Work

If your piece shifts mid-drill, it’s game over. I use clamps to hold it firm against a flat surface. For smaller pieces, I sandwich them between wood blocks or use a soft vise.

🔹 Step 3: Choose the Right Bit

Carbide bits are my go-to, but if I’m working with thinner sheets, diamond-tipped bits also work great. Avoid twist bits—they chew up the fibers and leave a mess.

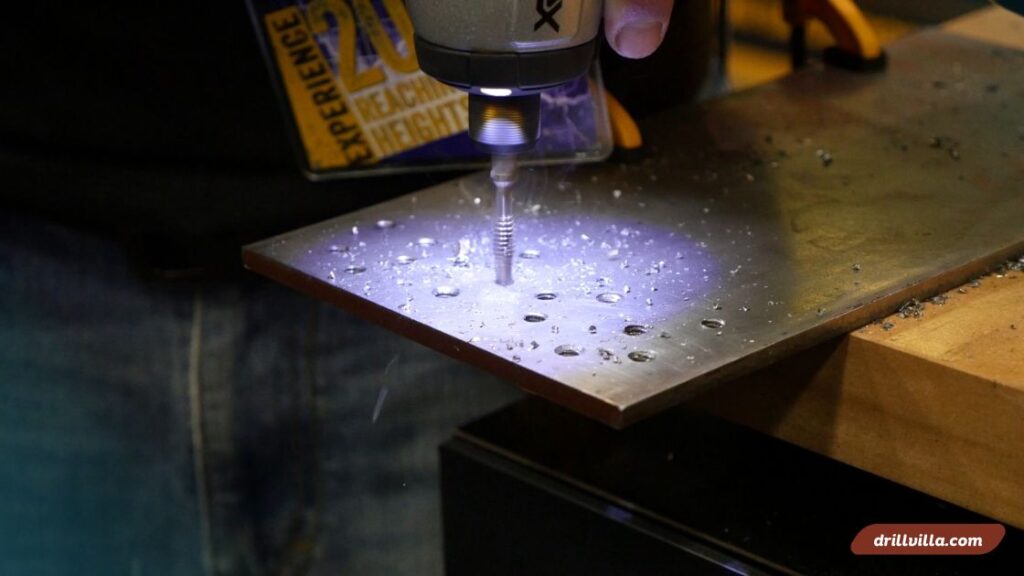

🔹 Step 4: Start Drilling…Slowly

I position the bit exactly where I want to drill and start with slow, gentle pressure. No need to rush. Let the bit do the work.

- Tip: Don’t push too hard! If you feel resistance, back off and clear out the dust.

🔹 Step 5: Break Through Carefully

As the bit breaks through the other side, go extra slow. I usually support the back with a wood block to stop any splintering.

What Can Go Wrong—and How I Fix It

Trust me, things will go wrong at some point. Here are common issues I’ve run into, plus how I fix them.

🚩 Delamination

Problem: The fibers start separating between layers.

Fix:

- Use sharper bits.

- Clamp between two pieces of wood to stabilize layers.

- Drill at a slower speed with less pressure.

🚩 Frayed Edges

Problem: The hole looks fuzzy and messy.

Fix:

- Tape over the hole site.

- Switch to brad point or diamond-tipped bits.

- Sand lightly after drilling (wear a mask!).

🚩 Cracking

Problem: Hairline cracks show up around the hole.

Fix:

- Drill a pilot hole first.

- Reduce pressure.

- Always support the back with a block.

My Top 10 Tips for Clean Holes Every Time

Here’s my rapid-fire list that I wish I had from the start:

- Use sharp bits—always.

- Tape both sides of the drill area.

- Drill perpendicular to the surface.

- Clamp everything down.

- Clear dust often during drilling.

- Wear a dust mask (carbon fiber dust is harmful).

- Start with a smaller pilot hole.

- Don’t skip backing material underneath.

- Keep a steady hand—no wobbling.

- Take your time—rushing ruins everything.

Drill Bit Comparison Table

Here’s a quick comparison of the types of bits I’ve used:

| Drill Bit Type | Works on Carbon Fiber? | Notes |

|---|---|---|

| Carbide | ✅ Excellent | Best choice, long life |

| Diamond-tipped | ✅ Good | Smooth cut, expensive |

| Brad Point | ✅ Okay | Good for small holes |

| Twist Drill | ❌ Bad | Causes fraying, splintering |

| Wood Bit | ❌ Very Bad | Dulls quickly, rough holes |

Safety Tips You Shouldn’t Ignore

This stuff isn’t just about clean holes—it’s also about your health.

- Wear a respirator or N95 mask: Carbon fiber dust is a lung irritant.

- Goggles are a must: You don’t want fibers in your eyes.

- Gloves help, especially when handling sharp edges.

Real-Life Story: My First Disaster and What I Learned

I’ll never forget my first attempt. I was modifying a carbon fiber drone arm—feeling confident with a shiny new twist bit and my trusty power drill. Bad move. The bit caught the fibers, ripped them outward, and left a jagged mess.

I tried to patch it with epoxy, but the structural damage was done. That lesson cost me $70 and two hours of frustration.

Now? I take it slow, prep carefully, and stick to the hand drill. It’s peaceful, even kind of therapeutic once you get the rhythm.

FAQs On A Guide To Hand Drilling In Carbon Fiber Composites

❓ Can I use a regular drill bit for carbon fiber?

Not recommended. Regular bits dull fast and cause fraying. Use carbide or diamond-coated bits.

❓ How do I prevent delamination?

Use sharp bits, tape both sides, clamp the piece, and drill slowly.

❓ Is carbon fiber dust dangerous?

Yes. It can irritate your lungs and eyes. Always wear protection.

❓ Do I need a pilot hole?

For thick sheets, yes. Start small and work your way up to the final diameter.

❓ Can I use a power drill?

Only if you’re experienced and have the right setup—like a drill press with speed control. Otherwise, stick to hand drilling.

Final Thoughts

Hand drilling carbon fiber composites might sound intimidating, but once you get the hang of it, it’s really not that bad. Actually, I’ve come to enjoy the process—quiet, focused, and satisfying when that clean hole pops out just right.

So if you’re about to take on your first project, remember this: slow is smooth, and smooth is fast. Respect the material, use the right tools, and take your time.

If I can go from cracked drone arms to smooth, precision-cut carbon parts, you absolutely can too.