Are you tired of struggling with rough, cracked holes every time you drill into wood, MDF, or other surfaces? You’re not alone.

Choosing the right drill bit can make all the difference between a clean, smooth hole and a frustrating mess. Imagine finishing your project with perfect holes that look professional and hold strong. You’ll discover exactly which drill bits work best to protect your materials and give you flawless results every time.

Keep reading, and you’ll never worry about cracking or splintering again.

Credit: www.lathamshardware.co.uk

Article Summary

Choosing The Right Drill Bit

Choosing the right drill bit is key to making clean holes in wood, MDF, or other surfaces. The wrong bit can cause cracking or splintering. Picking the right drill bit helps you work faster and keep your materials safe. Understanding the types and materials of drill bits helps you select the best one for your project.

Types Of Drill Bits For Wood And Mdf

Spade bits cut large holes quickly in wood and MDF. They have a flat, paddle shape with sharp edges. For clean holes, brad point bits are better. They have a pointed tip that keeps the bit steady. For precise, small holes, twist bits work well. They are common and easy to find. Hole saws create bigger holes but need steady control to avoid splintering. Choose the bit type based on the hole size and material thickness.

Material And Coating Considerations

High-speed steel (HSS) bits are strong and work well on softwood and MDF. Carbide-tipped bits last longer and handle harder materials. Coatings like titanium or black oxide reduce friction and heat. They keep the bit sharp and extend its life. A good coating also helps make smoother cuts. Always match the drill bit material and coating to your work surface for best results.

Credit: www.stinehome.com

Drill Bit Features For Clean Holes

Choosing the right drill bit is key to making clean holes in wood, MDF, or other surfaces. Certain features help prevent cracking and splintering. Understanding these features can improve your drilling results and save material.

Drill bits designed for clean holes have sharp cutting edges and specific tip designs. These features control how the bit cuts through the material. They also reduce tear-out and breakage around the hole.

Sharpness And Cutting Edges

Sharp cutting edges cut wood fibers smoothly. Dull edges tear and crush the material, causing rough holes. Bits with razor-sharp edges slice cleanly through surfaces.

Look for drill bits with ground or honed edges. These provide a smoother cut and less resistance. Sharp edges also reduce heat build-up, which can damage wood or MDF.

Point Angle And Tip Design

The point angle affects how the bit enters the material. A sharper angle (around 118 degrees) helps start the hole cleanly. It reduces splintering on the surface.

Special tip designs, like brad-point bits, have a small center point. This keeps the bit steady and prevents wandering. The spurs on the edges score the wood first, making a neat hole.

Choose bits with split points or self-centering tips for precise drilling. These designs cut faster and cleaner with less pressure.

Preventing Cracks And Splinters

Drilling clean holes in wood, MDF, or other surfaces without causing cracks or splinters requires care and the right technique. Cracks and splinters spoil the look and weaken the material. Preventing damage starts with simple steps anyone can follow.

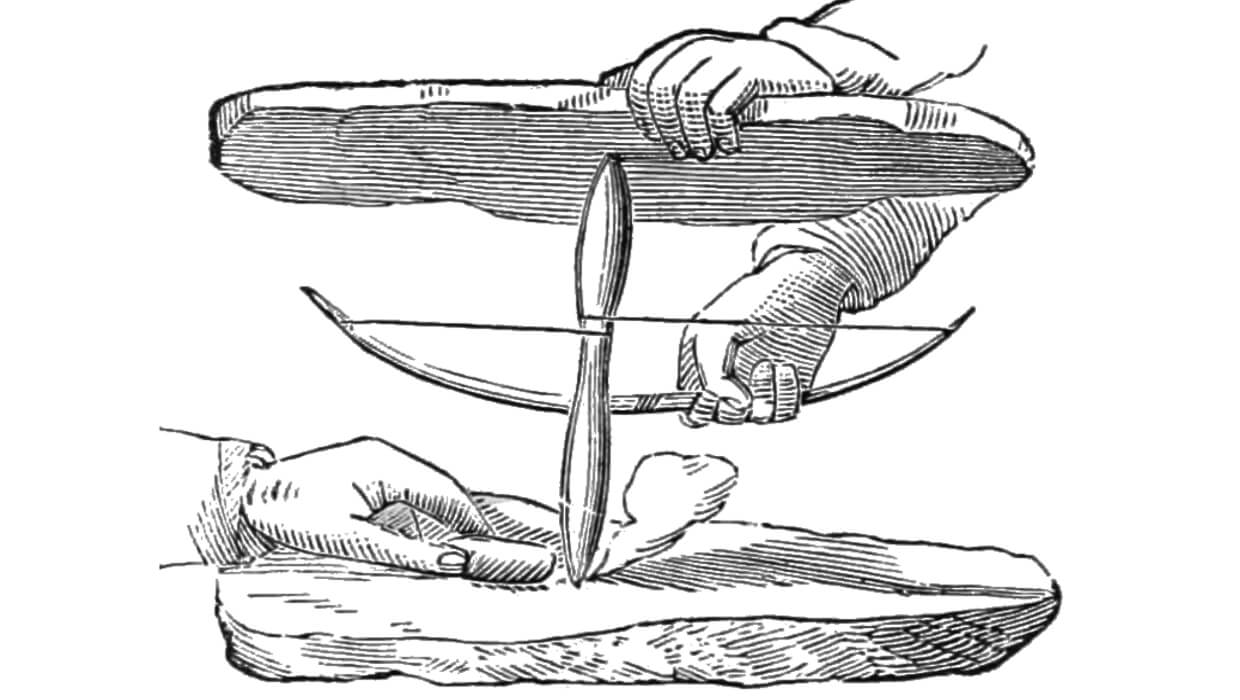

Using Backing Boards

Place a backing board under the workpiece before drilling. This supports the material and stops splinters from forming on the exit side. The backing board holds fibers in place, making a cleaner hole. It works well with thin or fragile materials like MDF or plywood.

Proper Drill Speed And Pressure

Use a slow to medium drill speed for wood and MDF. High speed can burn the wood or cause rough edges. Apply steady, gentle pressure. Pressing too hard can crack the surface or break the drill bit. Let the bit do the work, not your force.

Credit: www.homedepot.com

Best Practices For Drilling Mdf

Drilling into MDF requires care to avoid cracks and rough edges. MDF is dense and can chip easily under pressure. Following best practices helps create clean holes without damaging the surface. Proper techniques improve both the look and strength of the project.

Pre-drilling Techniques

Start by marking the drill spots clearly. Use a center punch or nail to make small indentations. This prevents the drill bit from slipping. Choose a sharp drill bit made for wood or MDF. A brad point bit works well to reduce splintering. Drill slowly and steadily, without forcing the bit. For larger holes, drill a small pilot hole first. This reduces pressure on the MDF and avoids cracking.

Handling Dust And Debris

MDF produces fine dust that can clog drill bits. Use a vacuum or brush to clear dust often. This keeps the drill bit sharp and cool. Clear dust also helps see the drill spot clearly. Wear a mask to avoid breathing MDF dust. Clean holes look smoother and are easier to finish. Proper dust control extends tool life and improves safety.

Alternatives To Standard Drill Bits

Standard drill bits can sometimes cause wood, MDF, or other surfaces to crack. Choosing the right drill bit helps make clean holes without damage. Some drill bits work better for these materials than regular ones. These alternatives provide smoother results and reduce splintering or cracking.

Forstner Bits

Forstner bits create flat-bottom holes with clean edges. They cut smoothly and reduce tear-out on wood and MDF. These bits are perfect for precise holes and overlapping holes. Their sharp edges help control the drilling process. Forstner bits give a neat finish without rough edges.

Spade Bits

Spade bits are wide and flat with a pointed tip. They drill large holes quickly in wood and soft materials. The sharp tip keeps the bit steady and centered. Spade bits work well for rougher cuts but can cause splintering on delicate surfaces. Use them with care for cleaner holes.

Brad Point Bits

Brad point bits have a sharp center point and spurs on the edges. The center point guides the bit precisely. Spurs cut the edges cleanly, reducing splintering. These bits are ideal for wood and MDF. They create smooth holes with less cracking and tear-out.

Maintaining Your Drill Bits

Maintaining your drill bits helps keep them sharp and effective. Well-maintained bits create clean holes in wood, MDF, and other surfaces. They reduce the chance of cracking or splintering. Regular care also extends the life of your drill bits. Simple steps can make a big difference in your drilling results.

Sharpening Tips

Dull drill bits cause rough holes and can damage materials. Use a sharpening tool or a fine file to restore the edge. Hold the bit at the correct angle while sharpening. Sharpen both cutting edges evenly for balanced drilling. Check the tip often and sharpen before it gets too dull. Avoid overheating the bit during sharpening by cooling it with water.

Storage And Care

Store drill bits in a dry place to stop rust. Use a bit holder or case to keep them organized. Avoid dropping or banging bits to prevent chipping. Clean bits after use to remove wood dust and resin. Apply a light coat of oil to prevent corrosion. Proper care keeps bits ready for clean, precise holes every time.

Frequently Asked Questions

What Is The Best Drill Bit For Clean Wood Holes?

For clean holes in wood, use brad point bits. They have sharp tips that prevent splintering. These bits ensure precise, smooth cuts without cracking.

Can I Use A Spade Bit On Mdf Without Damage?

Spade bits can cause splintering on MDF edges. Instead, use a Forstner bit for cleaner, crack-free holes in MDF and similar surfaces.

How To Avoid Cracking When Drilling Wood Or Mdf?

Use sharp drill bits and drill at low speed. Apply steady pressure and avoid forcing the bit. Pre-drilling pilot holes also helps prevent cracks.

Are Forstner Bits Suitable For All Surfaces?

Forstner bits work well on wood and MDF for clean holes. However, they are not ideal for metal or masonry surfaces.

Conclusion

Choosing the right drill bit makes a big difference in your work. Use brad point bits for clean holes in wood and MDF. They reduce splintering and cracking. For harder surfaces, consider carbide or titanium-coated bits. Always drill slowly and steady to avoid damage.

Keep your drill bits sharp and clean for best results. With the right tools and care, you can get smooth, precise holes every time. Simple steps lead to better projects and less frustration. Give your work the attention it deserves.